Understanding Aluminium Extrusion and Its Core Advantages

What Is Aluminium Extrusion? The Fundamentals of the Process

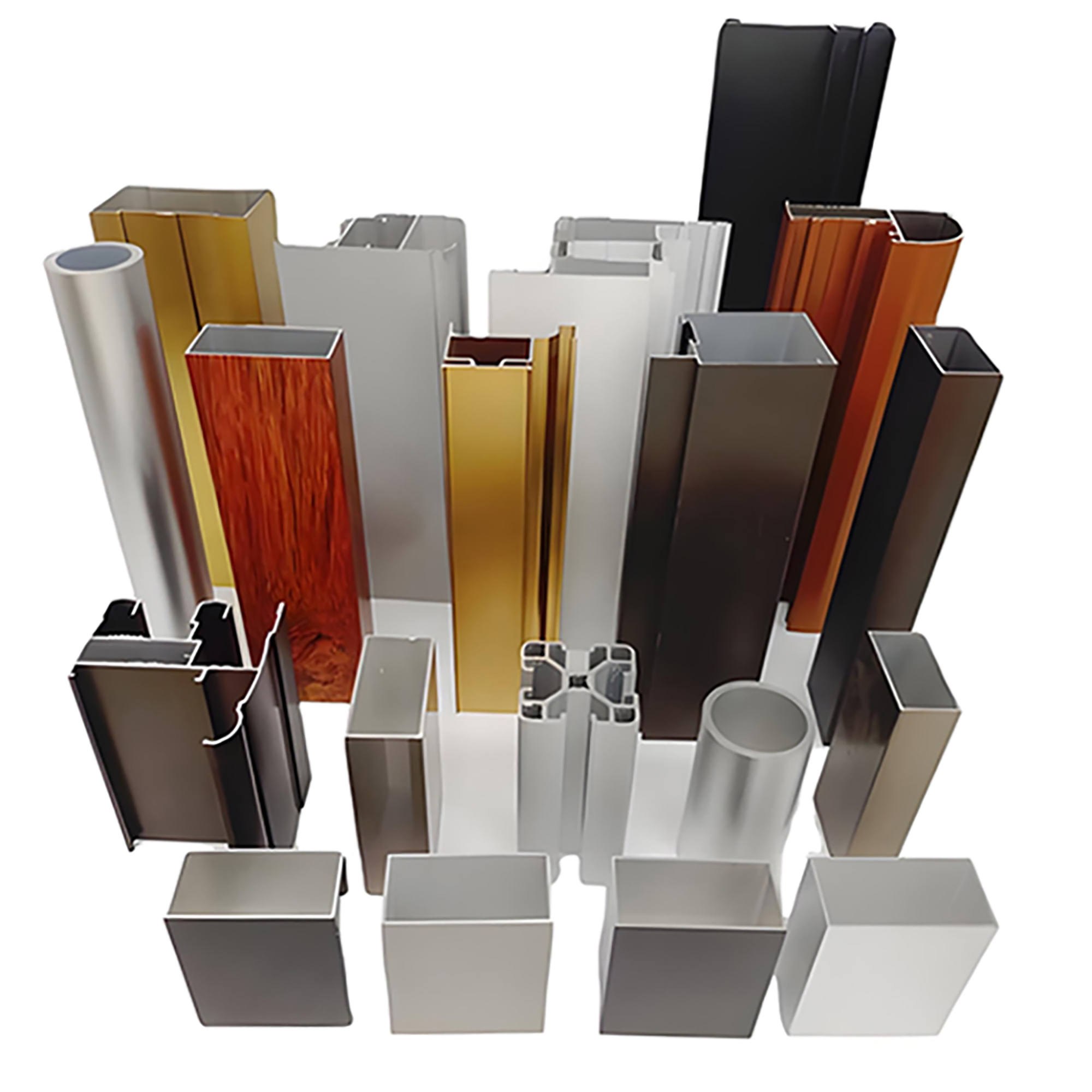

The aluminium extrusion process takes raw aluminium and shapes it into all sorts of complicated forms by pushing hot billets through specially designed dies. This happens when the metal gets heated to around 400 to 500 degrees Celsius and then squeezed under intense hydraulic pressure. What comes out are profiles with really intricate cross sections that keep most of aluminium's inherent strength but allow for shapes that just aren't possible with traditional casting or rolling methods. The main steps involve heating up the billets first, then the actual extrusion process itself, followed by rapid cooling (quenching) and finally some controlled aging treatment. A recent report from the International Aluminium Institute back in 2023 found something pretty interesting too: these extruded profiles can reach tensile strengths of about 350 MPa, which actually compares quite well to structural steel despite weighing only about 60% as much.

Why Use Aluminium Extrusion? Balancing Cost, Design Flexibility, and Performance

Three factors drive its widespread adoption:

- Cost efficiency: Extrusion generates less waste than CNC machining, reducing material costs by 15-30% (2024 industry report).

- Design freedom: Over 50% of manufacturers use extrusion for hollow sections and multi-channel designs impossible with other methods.

- Performance: Heat-treated 6000-series alloys maintain dimensional stability across -80°C to 150°C environments, making them ideal for demanding applications.

Advantages of Aluminium Extrusion for Lightweight Structures

When it comes to strength versus weight, extruded aluminum really stands out. The material has a strength-to-weight ratio around 125 kN m per kg, which is actually twice what we see in mild steel. What's interesting is how naturally resistant it is to corrosion thanks to its oxide layer. Tests show this protection works just as well as if steel had five times the coating thickness according to ASTM salt spray testing from 2022. For electric vehicle manufacturers looking to cut weight without sacrificing safety, aluminum makes sense. Battery enclosures made from this metal end up about 22 percent lighter than their steel counterparts but still pass all those important ISO crash tests. And let's not forget recycling potential either. More than 95 percent of extruded aluminum can be reused, making it a solid choice for companies trying to meet circular economy targets as noted by the International Aluminum Institute in their 2023 report.

The Science Behind Lightweight and High-Strength Properties of Aluminium Extrusion

Mechanical Properties of Extruded Aluminium: Strength and Lightweight Characteristics

Aluminum extrusions offer great strength while keeping things light because of how the metal works on a fundamental level. The stuff weighs only 2.7 grams per cubic centimeter, which is roughly what we get when dividing steel's weight by three. When manufacturers work with quality alloys such as 6061 or 6082, they can actually reach tensile strengths exceeding 300 megapascals. What does this mean in practice? Structures built with aluminum can handle similar loads to those made from steel but weigh around 40% less. That makes all the difference in applications where every gram counts, like building airplane frames or car bodies where engineers constantly battle against gravity.

| Property | Aluminium | Steel |

|---|---|---|

| Density (g/cm³) | 2.7 | 7.85 |

| Strength-to-Weight | High | Moderate |

Strength-to-Weight Ratio Comparison: Aluminium vs. Steel

Aluminium extrusions outperform steel in dynamic load scenarios. They deliver approximately 80% of steel’s load-bearing capacity at half the weight, as demonstrated in aerospace benchmarks. This efficiency reduces energy consumption in transportation systems by up to 15% while maintaining required safety margins (Industry Report 2023).

How Heat Treatment and Quenching Enhance Strength in Extruded Profiles

The thermal processing that happens after extrusion really brings out the best in aluminum products. Take T6 tempering for instance, which involves first heating the material to dissolve alloying elements and then artificially aging it later. This process can actually increase yield strength anywhere from 40% all the way up to 60% in those common 6000 series alloys we see so much of these days. When manufacturers control how quickly they cool down the metal during quenching, they prevent those pesky internal stresses from building up inside the material. What does this mean? The mechanical properties stay consistent across even complicated shapes and profiles. With these improvements, extruded aluminum can handle forces well beyond 450 MPa, making it perfect for demanding applications like electric vehicle battery housings and automotive suspension parts where reliability matters most.

Structural Performance: How Aluminium Extrusions Meet Engineering Demands

Area Moment of Inertia and Rigidity in Extruded Sections

Aluminium extrusions get their strength from smart design choices in their shape. When materials are placed further out from where stress concentrates, it creates better resistance against bending forces. Think about how I-beams work this way too. According to research published last year in the Structural Materials Journal, these kinds of extrusions offer around 27% more stiffness for the same weight compared to regular solid bars when used in bridges. What makes aluminium really stand out though is not just its clever geometry but also how light it naturally is. Together these factors allow for building lighter structures that still hold up under load without excessive sagging or deformation, something critical for many construction projects today.

Joint Configurations and Their Impact on Structural Integrity

How joints are designed really matters for how reliable structures end up being. When engineers weld joints with 6061-T6 aluminum alloy, these connections hold about 88% of what the original material can handle, which is pretty good for aerospace applications where weight savings count. For buildings and other architectural projects, bolted connections work better when they incorporate shear plates that help spread out the stress points rather than concentrating them in one spot. Some newer approaches have emerged too. Take those interlocking tongue and groove profiles we see increasingly in construction today. These allow components to snap together without tools, making assembly much faster. The bonus? Systems built this way typically weigh between 12 to 15 percent less than traditional fastened designs, something manufacturers love because lighter structures mean lower transportation costs and easier installation on site.

Custom vs. Standard Profiles: Trade-offs in Strength and Application

When engineers need something beyond standard specifications, custom extrusions get the job done but come with bigger price tags at the start. Recent industry data from 2025 shows these custom shapes can cut down on robotic part weights by around 19%, thanks to built-in mounting points. For manufacturers running batches over 8,000 units, this makes sense despite the roughly $12k tooling expense. On the flip side, standard profiles still work best when volume matters most and designs don't need constant tweaking. They save companies about three quarters of what they'd spend otherwise, which explains why so many solar panel frames stick with conventional profiles instead of going custom.

Real-World Applications of Aluminium Extrusion Across Industries

Automotive and Aerospace: Driving Innovation with Lightweight Aluminium Extrusions

The use of aluminium extrusion is changing the game for both automotive and aerospace industries because it allows engineers to create parts that are light yet strong enough to last. Car manufacturers apply this material to things like chassis frames, heat exchange systems, and even parts that help manage crashes all while making cars lighter without sacrificing their ability to protect passengers. When we look at airplanes, the same material helps designers build wings and fuselages that save fuel thanks to its impressive strength relative to its weight. According to recent research from the Automotive Materials Study released in 2023, replacing traditional steel components with aluminium extrusions cuts down on vehicle weight somewhere between 25% and 30%. That kind of reduction makes cars more efficient at burning fuel and reduces harmful emissions across the board.

Electric Vehicles: Battery Enclosures and Structural Efficiency

As electric cars become more popular on roads around the world, there's been a noticeable increase in need for extruded aluminum parts used in making battery boxes and structural components of vehicles. The material provides good protection against damage for those powerful battery packs inside EVs, plus it helps manage heat better than other options. Some major car companies have started incorporating special shaped aluminum pieces that actually contain built-in cooling passages right within their battery housings. This approach cuts down on how many separate parts are needed during production, maybe saving somewhere around 35-45% in assembly time according to industry insiders. What we see happening here is not just cost savings but also improvements across multiple areas including how well the vehicle performs overall, how long different components last before needing replacement, and most importantly how fast factories can put these new models together.

Architectural Frameworks and Bridges: Durability Meets Design

In construction, extruded aluminium combines aesthetic versatility with long-term corrosion resistance. Used in bridges and high-rise façades, these profiles form lightweight, load-bearing frameworks capable of enduring harsh environmental conditions. Their modular nature simplifies installation, cutting project timelines by up to 20% compared to traditional materials like concrete.

Case Study: Custom Aluminium Extrusions for Advanced Battery Solutions

One exciting development we're seeing is the use of multi channel extruded aluminum profiles as battery enclosures for electric vehicles. These one piece components actually combine several functions all in one go structural support, heat control, and protection against fires too. No longer do manufacturers have to assemble dozens of separate parts when everything can be formed together during production. The cost savings are pretty impressive around 15% lower manufacturing expenses according to some industry reports. Plus, batteries last longer this way. Looking at what's happening in automotive engineering right now, it's clear that extrusion technology isn't just changing one sector but reshaping manufacturing practices throughout various industries.

Optimizing the Aluminium Extrusion Process for Superior Results

From Billet to Profile: Key Stages in the Aluminium Extrusion Process

Extrusion starts when we heat those round metal billets to somewhere around 400 to 500 degrees Celsius so they become soft enough to work with. Big hydraulic presses then apply massive amounts of force, sometimes reaching up to 15,000 tons, which pushes the softened material through specially designed dies that shape it into whatever profile is needed. Once the extrusion is done, there's usually a quick cooling step called quenching that helps set the metal's physical characteristics. Then comes stretching to get rid of any built-up stress inside the material. Finally, various aging treatments like T5 or T6 tempering are applied depending on what kind of strength requirements need to be met. These days, many manufacturing plants have installed real time monitoring systems that keep an eye on both temperature and pressure levels during production. This has helped cut down waste significantly, with some operations reporting reductions in scrap materials anywhere from 8 percent all the way up to 12 percent over older methods.

Die Design and Alloy Selection: Tailoring Mechanical Properties

The shape and design of dies really matters when it comes to how materials move through them, what kind of surface finish we get, and whether the final product holds together properly. Take those 6000 series aluminum alloys for example. Manufacturers tend to build special channels into these dies so they can strike that right balance between making something strong enough while still being able to shape it easily. Most engineers go with either AA6063 or AA6061 because these grades extrude much better than say AA7075, needing about a third less force during production. Plus they resist corrosion better too. Good die design actually cuts down on problems such as visible seams or warped parts. And let's face it, defective products mean wasted time and money. Some factories report losing around 15 to 20 percent of their output to scrap simply because the dies weren't quite right for the job at hand.

Digital Simulation and AI-Driven Optimization in Modern Extrusion Workflows

FEA software can predict how materials behave during extrusion processes with around 92 to 97 percent accuracy these days. This means manufacturers can test dies virtually before ever running physical trials, saving time and money. A recent industry report from 2023 showed something interesting too AI powered systems have managed to reduce the number of trial runs needed by about half when they optimize things like press speed settings and cooling profiles for parts. The machine learning models behind this technology look at all sorts of historical production data and actually suggest different alloy compositions that could boost strength while reducing weight by anywhere between 8% and 15%. For companies working in mass production environments such as automotive manufacturing, getting these kinds of digital optimizations has become absolutely necessary if they want to stay competitive.

FAQs

What is aluminium extrusion used for?

Aluminium extrusion is used to create complex profiles for a multitude of applications, including automotive parts, architectural frameworks, aerospace components, and electric vehicle battery housings.

How does aluminium compare to steel in terms of strength-to-weight ratio?

Aluminium extrusions have a superior strength-to-weight ratio compared to steel, offering about 80% of steel’s load-bearing capacity at half the weight.

What are some benefits of using aluminium extrusions?

Key benefits include reduced material costs, design versatility, excellent strength-to-weight ratio, and great recyclability.

Can aluminium extrusions be recycled?

Yes, more than 95% of extruded aluminium can be recycled, which supports circular economy goals.

Table of Contents

- Understanding Aluminium Extrusion and Its Core Advantages

- The Science Behind Lightweight and High-Strength Properties of Aluminium Extrusion

- Structural Performance: How Aluminium Extrusions Meet Engineering Demands

- Real-World Applications of Aluminium Extrusion Across Industries

- Optimizing the Aluminium Extrusion Process for Superior Results

- FAQs