Choosing the right aluminum profile for your project is crucial for ensuring structural integrity, aesthetic appeal, and cost-effectiveness.

Aluminum profiles are versatile and can be used in various applications, from construction to manufacturing and beyond. In this article, we will explore the key considerations when selecting aluminum profiles, including types, applications, and industry trends.

Understanding Aluminum Profiles

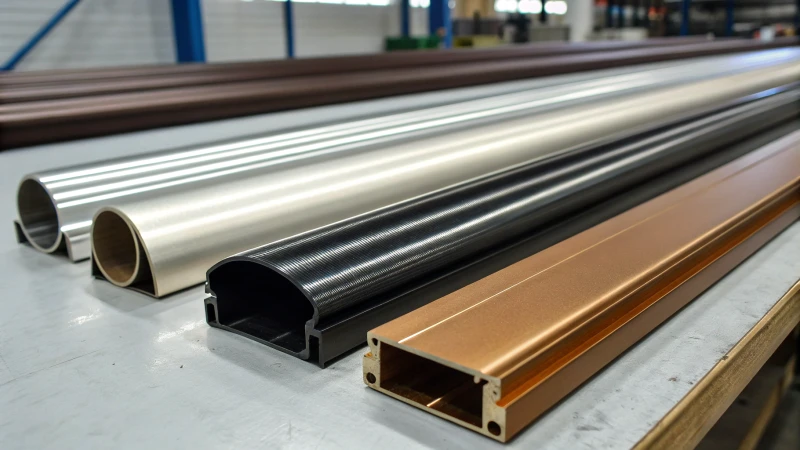

Aluminum profiles are extruded shapes made from aluminum alloys, designed to meet specific engineering requirements. They are lightweight, corrosion-resistant, and can be easily fabricated, making them ideal for a wide range of projects. Understanding the different types of aluminum profiles is the first step in making an informed choice. Common types include:

Standard Shapes: These include angles, channels, and beams that serve general construction purposes.

Custom Profiles: Tailored to meet specific project demands, these profiles can be designed for unique applications.

Structural Profiles: Used in load-bearing applications, these profiles offer enhanced strength and stability.

Key Considerations When Choosing Aluminum Profiles

When selecting an aluminum profile, several factors should be taken into account:

Load Requirements: Assess the load-bearing capacity needed for your project. This will help determine the thickness and type of profile required.

Environment: Consider the environmental conditions where the profile will be used. For example, marine environments may require profiles with higher corrosion resistance.

Aesthetic Preferences: The visual appeal of aluminum profiles can vary significantly. Choose a finish that aligns with your design vision, whether it be anodized, painted, or mill finish.

Cost Efficiency: Analyze the cost of different profiles and how they fit into your budget. Custom profiles may have higher upfront costs but can save money in the long run by reducing fabrication time.

Fabrication and Assembly: Consider how the profiles will be fabricated and assembled. Some profiles are easier to work with than others, which can impact project timelines.

Applications of Aluminum Profiles

Aluminum profiles are used in a wide array of applications, including:

Construction: For window frames, curtain walls, and structural components.

Automotive: In manufacturing lightweight vehicle components to improve fuel efficiency.

Electronics: For housing and heat sinks due to their thermal conductivity.

Furniture: In modern design for creating sleek and functional pieces.

Industry Trends in Aluminum Profiles

The aluminum profile industry is constantly evolving, driven by advancements in technology and changing market demands. Some notable trends include:

Sustainability: There is a growing emphasis on using recycled aluminum and sustainable manufacturing practices to reduce environmental impact.

Smart Manufacturing: The integration of automation and smart technologies in the production of aluminum profiles is enhancing efficiency and precision.

Customization: As projects become more specialized, the demand for custom aluminum profiles is increasing, allowing for greater flexibility in design and application.

In conclusion, selecting the right aluminum profile for your project involves careful consideration of various factors, including load requirements, environmental conditions, aesthetic preferences, and cost efficiency. By staying informed about industry trends and understanding the unique properties of different profiles, you can make a choice that not only meets your project's needs but also contributes to its overall success.