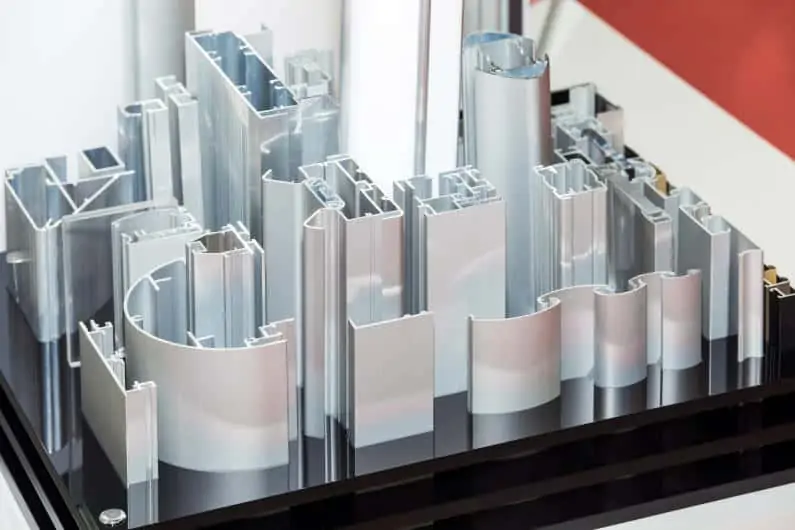

Aluminum is widely recognized for its lightweight and corrosion-resistant properties, making it a preferred choice in various industries, from aerospace to automotive.

However, to further enhance its durability and performance, innovative surface treatment technologies have emerged, revolutionizing how aluminum components are treated and utilized.

The first significant advancement in aluminum surface treatment is the development of anodization techniques.

Anodization not only improves the corrosion resistance of aluminum but also enhances its aesthetic appeal. This electrochemical process creates a protective oxide layer, significantly increasing the material's lifespan. By varying the anodization process parameters, manufacturers can achieve different thicknesses and colors of the oxide layer, allowing for customization based on specific application requirements.

Another noteworthy innovation is the introduction of advanced coatings, such as nano-coatings and hybrid coatings.

These coatings provide a robust barrier against environmental factors, including moisture, UV radiation, and chemicals. Nano-coatings, in particular, are engineered at the molecular level to create a protective layer that is both thin and highly effective. This innovation not only preserves the aluminum's natural properties but also enhances its mechanical strength, making it suitable for demanding applications.

In recent years, the adoption of environmentally friendly surface treatment methods has gained traction.

Traditional methods often involve hazardous chemicals that can harm the environment. However, new eco-friendly alternatives, such as bio-based coatings and chemical-free anodization processes, are being developed. These innovations not only comply with stringent environmental regulations but also appeal to a growing market of environmentally conscious consumers and businesses.

Moreover, surface treatment technologies are increasingly integrating digital solutions.

The use of smart sensors and IoT technology allows for real-time monitoring of the surface treatment processes. This data-driven approach enables manufacturers to optimize treatment parameters, reduce waste, and improve product quality. The integration of technology into surface treatment processes exemplifies the industry's shift towards more efficient and sustainable manufacturing practices.

As we look to the future, the trend of enhancing aluminum surface treatment is expected to continue.

Innovations such as 3D printing combined with advanced surface treatments will likely open new avenues for product development. Additionally, as industries strive for sustainability, the demand for eco-friendly surface treatments will drive further research and development in this field. The continuous evolution of aluminum surface treatment technologies promises to deliver even greater durability and performance, meeting the ever-changing needs of various industries.

Table of Contents

- Aluminum is widely recognized for its lightweight and corrosion-resistant properties, making it a preferred choice in various industries, from aerospace to automotive.

- The first significant advancement in aluminum surface treatment is the development of anodization techniques.

- Another noteworthy innovation is the introduction of advanced coatings, such as nano-coatings and hybrid coatings.

- In recent years, the adoption of environmentally friendly surface treatment methods has gained traction.

- Moreover, surface treatment technologies are increasingly integrating digital solutions.

- As we look to the future, the trend of enhancing aluminum surface treatment is expected to continue.