Understanding the Basics of Aluminium Extrusion

What is aluminium extrusion?

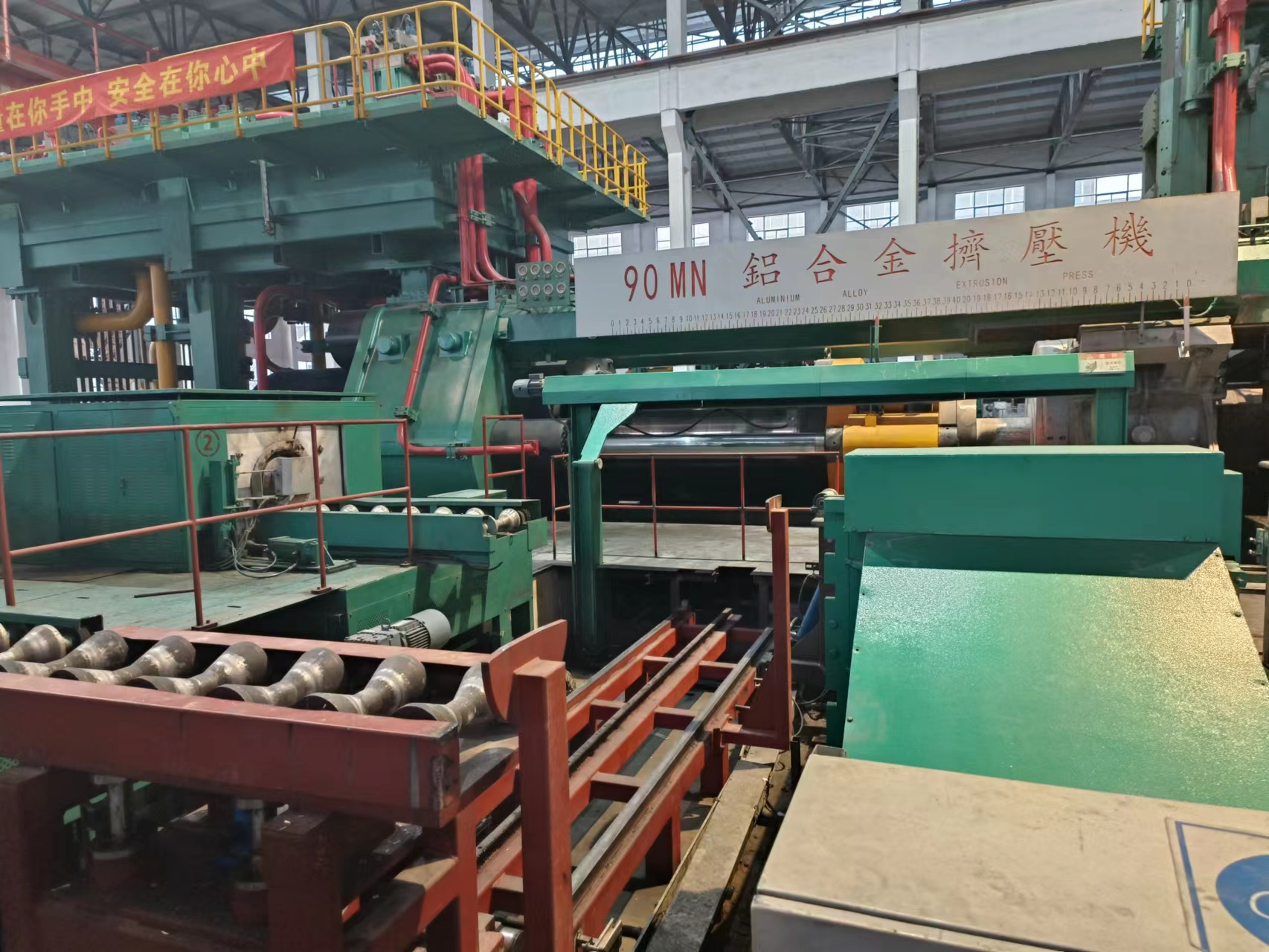

The aluminium extrusion process takes raw aluminium alloys and shapes them into long, continuous profiles with specific cross sections. When billets get heated between around 480 to 500 degrees Celsius, they soften enough to be pushed through specially made steel dies under massive hydraulic pressure sometimes reaching as high as 15,000 tons. What comes out the other end are these incredibly light yet strong structural parts. Interestingly, about six out of ten buildings today actually rely on this technique for their framework, and we see similar applications across various transport industries where weight savings really make a difference.

How does the aluminium extrusion process work?

- Die Preparation — CNC-machined tool steel dies shape the profile

- Billet Heating — Infrared ovens uniformly heat aluminium logs to 480—500°C

- Extrusion — A ram pushes softened metal through the die at 5—50 m/min

- Quenching — Forced-air or water cooling ensures dimensional stability

- Stretching & Cutting — Mechanical stretching corrects warping before sawing to length

Recent advancements like real-time pressure monitoring systems reduce material waste by 18% while maintaining ±0.5mm tolerances on complex geometries.

A simplified overview of the aluminium extrusion process

Think of what happens when kids push play dough through cookie cutters, then imagine doing something similar with metal at factory scale. That's basically how aluminium extrusion works. The basic idea is taking solid metal and turning it into all sorts of useful shapes like beams, channels, and those cooling fins we see on electronics. There are basically three main steps involved here. First comes heating up the metal until it gets soft enough to work with. Then comes the actual pressing part where the heated metal gets forced through dies to create specific profiles. After that there's some finishing touches needed too, mostly cooling down the product and cutting it to length as required. Because this whole process flows so smoothly from start to finish, many manufacturing plants can churn out around 500 meters worth of these metal profiles every single hour without stopping.

The Core Principles Behind Aluminium Extrusion

Heat, Pressure, and Deformation: Key Forces in Extrusion

The process of aluminium extrusion depends on three main factors working together: heat, pressure, and careful shaping. When billets are brought up to around 400 to 500 degrees Celsius, their resistance drops by about 80% but they still hold their basic structure. Big hydraulic machines then press down with forces between 15 thousand and 35 thousand pounds per square inch to force the softened metal through special dies. This creates those complex shapes we see so often, and the metal gets deformed over 95% of the time during this process. What makes this method so valuable is that even after all this manipulation, the aluminium keeps its natural protection against rust and maintains that great balance between weight and strength that makes it so popular across industries.

Direct vs. Indirect Aluminium Extrusion: A Comparative Analysis

| Parameter | Direct Extrusion | Indirect Extrusion |

|---|---|---|

| Die Movement | Stationary | Moves with ram |

| Friction | High (billet-die contact) | Reduced by 30—40% |

| Energy Use | 15—20% higher | More efficient |

| Applications | Simple cross-sections | Precision aerospace parts |

Direct extrusion dominates industrial applications due to simpler tooling, while indirect methods excel where low friction and tight tolerances are critical.

Hot, Warm, and Cold Extrusion: The Role of Temperature

Temperature directly influences material flow and final properties:

- Hot Extrusion (350—500°C): Standard for structural alloys, balancing formability and speed

- Warm Extrusion (150—350°C): Reduces oxidation while preserving 85% of hot extrusion ductility

- Cold Extrusion (Room Temp): Increases tensile strength by 15—25% via work hardening

Studies show temperature deviations greater than 10°C can increase surface defects by 18%, emphasizing the need for precision control.

Types and Design Capabilities of Aluminium Extrusion Profiles

Solid, Hollow, and Semi-Hollow Profiles: Common Types of Aluminium Extrusion

The classification of aluminium extrusion profiles largely depends on their cross section shape. Solid types like rods and bars have continuous material throughout, making them great choices for things like structural beams and machine parts where strength matters most. Hollow profiles come with empty spaces inside, which gives them excellent strength while keeping weight down. That's why they're so popular in car frames and building exteriors. Then there are semi-hollow designs that have some internal space but not complete voids. These strike a good middle ground between complicated manufacturing needs and practical efficiency, often showing up in windows and insulation applications across various industries.

| Profile Type | Key Characteristics | Common Applications |

|---|---|---|

| Solid | Full material cross-section | Load-bearing beams, railings |

| Hollow | Internal cavities reduce weight | Vehicle chassis, HVAC ducts |

| Semi-Hollow | Partial voids for insulation/alignment | Door frames, solar panel mounts |

Design Capabilities and Limitations of Extruded Profiles

While capable of producing intricate shapes, aluminium extrusion has practical limits. Wall thickness below 1.5 mm risks deformation during cooling, and tight tolerances (±0.13 mm) require advanced die engineering. Multi-port dies now enable up to six interconnected chambers in hollow profiles, though production costs rise 18—22% compared to standard designs.

Case Study: Custom Rail System Using Complex Hollow Extrusions

A recent transportation project utilized hollow aluminium profiles with internal cable channels and external T-slots for modular assembly. The design achieved 40% weight reduction versus steel while meeting ISO 9001:2015 fatigue resistance standards. This demonstrates how tailored extrusions solve engineering challenges through material efficiency and integrated functionality.

Step-by-Step Aluminium Extrusion Manufacturing Process

From billet to product: The 10-step aluminium extrusion procedure

Die preparation starts things off, where those precision tools get heated up around 450 to 500 degrees Celsius. This helps materials flow better during processing. The billets themselves need some time in the oven too, about four to six hours at temperatures between 500 and 550 degrees Celsius to work out any internal stress issues. After that comes the pressing stage, which happens under pretty intense pressure ranging from 15 thousand to 35 thousand pounds per square inch. There are several important steps after pressing: quenching to cool things down quickly, stretching alignment to fix any warping problems, and various aging treatments like T5 or T6 tempers depending on what kind of hardness is needed for the final product. Many modern manufacturing plants now have these smart sensor systems built right in. These AI powered devices keep track of billet temperatures with about plus or minus five degree accuracy while monitoring how fast the ram moves. Plants using this technology report seeing reductions in scrap material somewhere around 20% give or take.

Why preheating and homogenization ensure extrusion quality

Preheating billets to 400—500°C reduces extrusion forces by 18% while preserving structural integrity. Homogenization dissolves alloy segregation, creating uniform grain structures that prevent cracking—especially vital for aerospace-grade components. Combined with real-time thermal profiling, these steps cut surface defects by 35% compared to non-homogenized aluminium.

Key Factors Influencing Quality in Aluminium Extrusion

Material selection, die design, and temperature control

Material choice determines application suitability, while die design governs profile accuracy—optimized geometries can improve production efficiency by 15—20%. Temperature control is equally crucial; maintaining billet temperatures between 425°C and 475°C reduces surface defects by 30%.

Die wear and alloy composition: Hidden variables in consistency

Die wear alters tolerances by up to 0.8% per 10,000 cycles, necessitating predictive maintenance. Alloys with 0.15—0.25% magnesium exhibit 40% better wear resistance than standard 6000-series formulations.

AI-driven monitoring systems reduce defects by 35% (Journal of Materials Processing Technology, 2023)

Machine learning algorithms detect minute variations in pressure (±2.5 bar) and temperature (±3°C), enabling immediate corrections that prevent substandard output.

Can recycled aluminium maintain structural integrity in extrusion?

Post-industrial scrap processed through advanced filtration achieves 98.5% purity. Tensile tests show properly heat-treated recycled 6063 alloy meets 96% of virgin material strength, confirming its viability for structural applications.

FAQ

What is the main advantage of aluminium extrusion?

Aluminium extrusion offers a balance between strength and lightweight properties, making it ideal for construction and transportation industries where weight savings are crucial.

How do temperature variations affect aluminium extrusion?

Temperature variations greater than 10°C can increase surface defects by 18%, highlighting the importance of precision control in the extrusion process.

Can recycled aluminium be used effectively in extrusion?

Yes, recycled aluminium processed through advanced filtration achieves high purity and retains structural integrity, making it viable for extrusion applications.