Pielāgotās Aluķīma Izvilkšanas Procesa Sapratne

Aluķīma Izvilkšanas Process Skaidrots

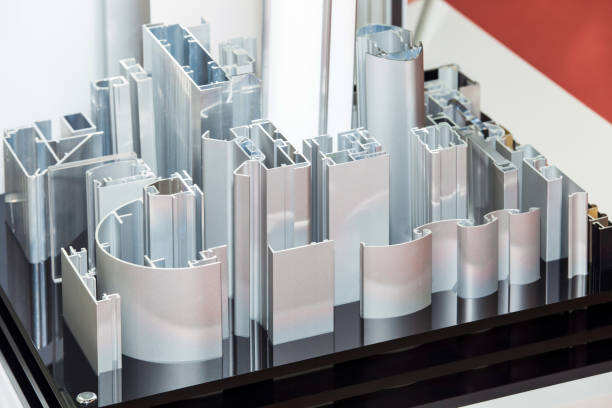

Individuāli izgatavotas alumīnija ekstrūzijas process sastāv no cietu alumīnija bluķu pārveidošanas dažādās sarežģītās formās, izmantojot siltumu un spiedienu. Vispirms tiek uzsildīti bluķi, līdz tie kļūst pietiekami mīksti, lai ar tiem varētu strādāt, tomēr joprojām saglabā savu cieto struktūru. Kad materiāls ir gatavs, to caur īpašiem veidnēm piespiež, lai iegūtu vajadzīgo formu, kas nepieciešama gala produktam. Šīs metodes vērtību alumīnija izstrādājumu ražošanā nosaka tās pielietojamība. Mēs varam izgatavot visu – no vienkāršām stīgām līdz sarežģītiem komponentiem, kas atbilst precīziem specifikāciju prasībām dažādām nozarēm un pielietojumiem.

Alumīnija ekstrūzijas darbā temperatūra un spiediens ir ļoti svarīgi ražošanas procesā. Pareiza siltuma iestatīšana ļauj saglabāt metālu pietiekami mīkstu, lai ar to varētu strādāt, vienlaikus saglabājot tā stiprības īpašības. Attiecībā uz spiediena iestatījumiem ražotājiem ir jānodrošina precīza vērtība, lai kausētais alumīnijs faktiski pieņemtu tieši to formas, kāda ir matricai, kuru izmanto. Šo divu faktoru optimālās kombinācijas atrašana ir izšķiroša nozīme, izgatavojot individuālus alumīnija komponentus. Pat nelielas kļūdas šeit var izraisīt nestandarta produktus vai kvalitātes problēmas turpmāk, ko neviens nevēlas, strādājot ar precīzijas detaļām rūpnieciskām lietošanas jomām.

Alumīnija ekstrūzijā tiek izmantoti dažādi matricu veidi, no kuriem katrs nodrošina atšķirīgas priekšrocības atkarībā no tā, ko nepieciešams ražot. Tiešajā ekstrūzijā matricas tiek fiksētas un karstās sagataves tiek izspiestas caur tām, tādējādi to padarot par ideālu vienkāršu formu, piemēram, cauruļu vai stieņu ražošanai. Netiešā ekstrūzija darbojas citādi – matrica pārvietojas ap sagatavi, ļaujot ražotājiem izgatavot sarežģītas formas ar gludāku virsmu. Šīs metodes nav vienkārši tehniskas atšķirības – tās faktiski nosaka, vai produkts būs ar pamata funkcionalitāti vai arī papildfunkcijām. Uzņēmumiem, kuriem ir nepieciešami specializēti komponenti, šo atšķirību izpratne kļūst par būtisku faktoru, svarīgi balansējot izmaksas pret veiktspējas prasībām ražošanas procesos.

Korektā aliejuma izvēle atsevišķiem projektiem

Izvēloties pareizo alumīnija sakausējumu, tas ir izšķirošais faktors jebkurā individuālajā izgatavošanā. Dažādi sakausējumi piedāvā savas stiprības, attiecībā uz izturību, svaru un izturību pret koroziju un vēathera bojājumiem. Izvēle ietekmē, cik ilgi izstrādājums būs izmantojams un cik labi tas darbosies pēc izgatavošanas. Tāpēc svarīgi ir sakausējuma specifikācijas precīzi pielāgot reālajam darbam, ko veic uz specializētiem projektiem.

Runājot par alumīnija ekstrūzijām, lielākā daļa ražotāju izvēlas vai nu 6061, vai 6063 sērijas sakausējumus. 6061 tips izceļas arī ar lielu izturīgumu, nezaudējot pārāk daudz citos aspektos. Tāpēc to bieži izmanto vietās, kur lietas jāiztur sasprindzinājumā, piemēram, konstrukciju rāmjos vai detaļās, kas jāiztur agresīvā vidē. Tā izturība pret koroziju un spēja tikt veidota dažādās formās padara to par diezgan universālu materiālu. Savukārt 6063 sakausējums ir kļuvis par iecienītu arhitektu un dizaineru vidū, kuriem ir tikpat svarīgi izskats kā funkcionalitāte. Šis sakausējums labi liecas apstrādes laikā un nodrošina virsmas, kuru pabeigšanai pēc tam nepieciešams minimāls apstrādes darbs. Personām, kas strādā pie pielāgotiem projektiem ar alumīniju, ir svarīgi zināt, kad izvēlēties vienu vai otru sakausējumu, jo tas var ievērojami ietekmēt gan veiktspēju, gan estētiku nākotnē.

Pareiza sakausējuma izvēle ietekmē ne tikai to, kā kaut kas izskatās, bet arī kāda pabeigšana un siltuma apstrāde ir nepieciešama, kas galu galā maina tā darbību un izskatu. Piemēram, ņemot anodēšanu, daži metāli šo procesu pārnes daudz labāk nekā citi, nodrošinot ilgāku aizsardzību pret rūsēšanu un vienlaikus skaistāku izskatu. Katram metālam ir savas īpašības, kas padara noteiktas pabeigšanas veidus efektīvākus, tāpēc pareiza materiāla izvēle ir ļoti svarīga, ja kāds vēlas, lai alumīnija detaļas pēc apstrādes izskatās labi un veiksmīgi veiktu savas funkcijas.

Pielāgotu aluminija profilu piemēri nevienalīdzīgos projektos

Arhitektūras un būvniecības inovācijas

Pasūtījuma izgatavoti alumīnija profili maina mūsu uztveri par ēkām šodien, jo tie apvieno vieglumu ar izturību un ir pieejami visdažādākajos formās un apdarei. Mēs to redzam visur apkārt – ēkās alumīnija ekstrūzijas veido svarīgas struktūras daļas, piemēram, lielās logi un ārējās sienas. Arhitekti ļoti vērtē šos materiālus, jo tie projektēšanas procesā nodrošina lielu brīvību, veidojot izturīgas un estētiski patīkamas ēkas. Apskatiet jebkuru modernu debesskrāpi vai greznu fasādi – aiz tām noteikti slēpjas individuāli sagriezts alumīnijs, kas nodrošina gludas līnijas un pārliecinošu izteiksmi.

Transporta un automobiļu risinājumi

Alumīnija ekstrūzijas transporta nozarē kļuvušas ļoti svarīgas, jo tās palīdz samazināt degvielas patēriņu un kopējo transportlīdzekļu svaru. Automobiļu ražotāji šodien izmanto pielāgotas alumīnija formas gandrīz visur — konstrukcijās, dzesēšanas sistēmās, pat automašīnu korpusa daļās. Tas ļauj viņiem izgatavot vieglākas automašīnas, kas pie tam uzlabo braukšanas īpašības. Vēl viena liela alumīnija priekšrocība ir tā, ka to var viegli pārstrādāt atkārtoti. Tā kā visā nozarē pieaug vides aizsardzības rūpes, tas kļūst par svarīgu pārdošanas argumentu. Kad automobiļu uzņēmumi sāk izmantot vairāk alumīnija savos dizainos, viņi ne tikai rūpējas par vidi; viņi iegūst arī reālus priekšrocības, jo alumīnijs nodrošina lielu izturību, gandrīz nemainot svaru.

Specializētas rūpnieciskās un patēriņa lietojumprogrammas

Pašlaik pasūtījuma kārtā izgatavoti alumīnija izstrādājumi nonāk dažādās rūpnieciskās vides. Mēs runājam par lietām, piemēram, skavām, rāmjiem un balstkonstrukcijām dažādās inženierzinātnēs un ražošanas operācijās. Attiecībā uz ikdienas priekšmetiem arī sadzīves ierīces un elektroniskās ierīces tiek ievērojami uzlabotas, izmantojot īpaši izstrādātas alumīnija detaļas. Šīs detaļas ne tikai padara izstrādājumus labāk darbojošos, bet arī padara tos skaistākus kopumā. Arvien vairāk patērētāju pieprasa alumīniju savos patēriņa preču izstrādājumos, kas norāda uz kaut ko lielāku, kas notiek tirgū. Ražotāji šķiet tiecas pēc vieglāku materiālu izmantošanas, kas joprojām ir izturīgi un vienlaikus ļauj izpausties kreatīvai dizaina izvēlei. Šis maiņas nav vienkārši par naudas ietaupīšanu. Uzņēmumi patiešām pārprojektē izstrādājumus, izmantojot pielāgotas ekstrudētas alumīnija formas, lai radītu labāku lietojāja pieredzi tiem, kas vēlas gan kvalitāti, gan stilu savās iegādēs.

Tīrais inženierdarbs sarežģītiem dizainiem

Alumīnija ekstrūzijas izceļas kā lieliska metode detalizētu dizainu ražošanai saskaņā ar ļoti konkrētiem nosacījumiem. Šīs ekstrūzijas atver daudzas iespējas dažādās nozarēs, sākot no specializētu alumīnija profiliem, kas izmantoti būvniecībā, līdz precīziem komponentiem, kas nepieciešami rūpnieciskajām iekārtām. Ekstrūzijas efektivitāti nosaka tās spēja ražot sarežģītas formas, saglabājot stingru izmēru precizitāti, kas nozīmē, ka detaļas darbojas uzticami, nezaudējot stiprumu. Pēdējā laikā datorizētās numeriskās kontroles (CNC) tehnoloģijā ir ticis panākts lielāks progress, kas ļauj ražotājiem sasniegt detalizētības līmeni, kas agrāk tika uzskatīts par nesasniedzamu, izmantojot tradicionālas izgatavošanas metodes. Tā kā CNC mašīnas var apstrādāt materiālu ar nesalīdzināmu precizitāti, alumīnijs turpina iegūt popularitāti salīdzinājumā ar konkurentiem, ražojot individuālus komponentus. Nozarēs, sākot no aviācijas un kosmosa līdz medicīnisko ierīču ražošanai, aizvien biežāk tiek izmantotas alumīnija ekstrūzijas, jo tās nodrošina gan daudzpusību, gan izcilu kvalitāti pielāgotās lietojumprogrammās.

Ilgtspēja un korozijas atgaidīšana

Alumīnijs patiešām izceļas, runājot par zaļo un ilgtspējīgo materiālu, galvenokārt tādēļ, ka to var pilnībā pārstrādāt bez kvalitātes zuduma. Alumīnija asociācija ziņo par kaut ko diezgan ievērojamu: aptuveni 75% no visā alumīnijā līdz šim izgatavotā joprojām tiek izmantots kaut kur, un nozarēs, piemēram, automašīnu būvniecībā un ēku celtniecībā, pārstrādes līmenis sasniedz vairāk nekā 90%. Šāda veida nepārtrauktā pārstrādājamība labi iederas tajā, ko uzņēmumi cenšas sasniegt ar saviem ilgtspējas mērķiem, vienlaikus samazinot oglekļa pēdas izmērus alumīnijā izgatavotiem izstrādājumiem. Vēl viena liela alumīnija priekšrocība ir tā izturība pret rūsas veidošanos un sabrukšanu. Alumīnija izstrādājumi ilgst daudz ilgāk, ja tiek pakļauti grūtiem apstākļiem. Patiesībā uz alumīnija virsmām dabiski veidojas plāna oksīda plēve, kas darbojas kā aizsardzība pret koroziju. Tādēļ alumīnijs ir lielisks materiāls ārā novietotiem izstrādājumiem vai tiem, kas atrodas ūdens tuvumā, piemēram, kuģiem un krasta struktūrām. Ilgāk izturīgi izstrādājumi nozīmē retāku nomaiņu, kas ilgtermiņā samazina gan remonta izmaksas, gan vispārējo vides ietekmi.

Izdevīga materiāla optimizācija

Individuāli izgatavotas alumīnija ekstrūzijas izceļas ar to, ka tās patiešām samazina materiālu atlikumus, kas ilgtermiņā ietaupa naudu. Kad uzņēmumi precīzi projektē profili atbilstoši katram konkrētam uzdevumam, salīdzinājumā ar citām metodēm paliek ievērojami mazāk metāla atgriezumu. Salīdzinot ar vecajām metodēm, piemēram, ar matricu liešanu vai injekciju formēšanu, alumīnija ekstrūzijai parasti ir daudz zemākas iekārtu izmaksas jau sākumā. Tas ir ļoti svarīgi, kad kādam ir nepieciešama kāda īpaša detaļa, bet viņš nevēlas tērēt milzīgas summas par rīku izgatavošanu tikai dažām detaļām. Tomēr, kad matrica ir izgatavota, ražošana faktiski kļūst daudz ātrāka. Šī metode labi darbojas gan lielos, gan vidējos apjomos — simtiem vai desmitiem vienību. Šādas elastības dēļ ražotāji var palielināt vai samazināt ražošanas apjomus atkarībā no faktiskajām pasūtījumu vajadzībām, neiztērējot lielu naudas summu. Tādēļ uzņēmumiem, kuri cenšas izmantot katru centu, vienlaikus iegūstot kvalitatīvas detaļas, alumīnija ekstrūzija bieži kļūst par ieteicamo izvēli.

Pielāgotu alumīnija profilu dizainēšana: no idejas līdz ražošanai

Pielāgotas beigas un funkciju īpašības

Izstrādājot individuālus alumīnija profilus, mēs patiesībā pārvēršam idejas par reāliem produktiem, izmantojot pielāgotus pabeigšanas paņēmienus un papildfunkcijas. Šodien alumīniju var pabeigt vairākos veidos. Anodēšana lieliski kalpo pret koroziju un ļauj izvēlēties daudzas krāsas. Pulverkrāsas pārklājums ir daudz izturīgāks un ilgstošāk izskatāks nekā parastā krāsa. Šie apstrādes veidi ne tikai pagarina izstrādājumu kalpošanas laiku, bet faktiski nodrošina alumīnija produktiem priekšrocības, kas nepieciešamas, lai konkurētu ar citiem produktiem uz veikalu plauktiem. Pievienojot īpašas iezīmes, piemēram, pielāgotas kanālus vai neparastas formas, izstrādājumi kļūst labāk pielāgoti paredzētajam mērķim, atverot iespējas dažādām radošām dizaina idejām. Apskatiet, ko pēdējā laikā ir paveikušas uzņēmumi automobiļu rūpniecībā vai tehnoloģiju jomā. Tie ir izmantojuši šos specializētos paņēmienus, lai izceltos starp konkurentiem, kuri piedāvā vispārīgus dizainus. Starpība starp labu un lielisku bieži vien ir atkarīga no tām sīkām detaļām, kas padara produktu patiešām unikālu.

Sadarbošanās ar izvilkšanas speciālistiem

Lai iegūtu labus rezultātus no pasūtījuma alumīnija profiliem, viss sākas ar ciešu sadarbību ar pieredzējušiem ekstrūzijas speciālistiem. Šie profesionāļi piedāvā praktiskas zināšanas, lai risinātu visus sarežģītos projektēšanas un prototipa izstrādes aspektus, nodrošinot, ka katrs profils atbilst projektā izvirzītajām prasībām. Kad projektētāji un izgatavotāji regulāri sazinās attīstības procesā, viņi var veikt pielāgojumus ceļā. Šī atkārtotā saziņa nodrošina, ka gala produkts ir efektīvi ražojams un darbojas pareizi. Laba komunikācija visā procesā ļauj visiem palikt uz vienas viļņu garuma un samazina neskaidrības, kas palēnina darbu. Projektu īstenošana, kurā izmanto šāda veida nepārtrauktu atsauksmi, parasti arī notiek gludāk, jo tiek izmantotas speciālistu zināšanas, ko tie ieguvuši darbā nozarē. Kāds ir gala rezultāts? Laika un līdzekļu ietaupījums, piegādājot gatavus produktus.