Peranan Profil Aluminium dalam Kejuruteraan Struktur Moden

Mengapa Industri Pembinaan Berpindah kepada Bahan Ringan

Syarikat pembinaan di seluruh dunia kini mempertimbangkan secara serius bahan yang mengurangkan berat tanpa mengorbankan keutuhan struktur. Profil aluminium menonjol dalam trend ini, mengurangkan berat sebanyak kira-kira 40 hingga 50 peratus berbanding pilihan keluli sambil masih mampu menahan beban yang serupa menurut laporan dari Global Construction Review tahun lepas. Bangunan yang lebih ringan bermakna kos bahan api yang lebih rendah apabila mengangkut bahan di tapak pembinaan dan semasa kerja pembinaan sebenar. Pengeluar ternama mengambil kesempatan daripada kemudahan lenturan dan pembentukan aluminium untuk membuat profil khas bagi bangunan tahan gempa bumi dan struktur modular yang kini semakin banyak dilihat di mana-mana. Sesetengah syarikat malah melaporkan bahawa mereka boleh mereka bentuk komponen terus di tapak kerja berkat fleksibilitas ini.

Bagaimana Profil Aluminium Meningkatkan Kekuatan dan Kestabilan Struktur

Profil aluminium hari ini boleh mencapai nisbah kekuatan terhadap berat yang sangat mengagumkan berkat kaedah pengeluaran yang lebih baik dan aloi yang diperbaiki. Ambil aluminium 6063-T6 sebagai contoh, ia mempunyai kekuatan tegangan sehingga kira-kira 241 MPa tetapi masih berat sekitar satu pertiga daripada keluli karbon. Bentuk saluran berongga sebenarnya menawarkan kekukuhan kilasan kira-kira 22% lebih tinggi berbanding yang padat menurut kajian dari Jurnal Kejuruteraan Bahan pada tahun 2022. Ini menjadikan profil-profil ini pilihan yang sangat baik apabila kita memerlukan kestabilan sisi ke sisi yang baik dalam struktur. Selain itu, mereka mempunyai kelenturan tersendiri yang membolehkan mereka berubah bentuk secara terkawal apabila mengalami tekanan, yang merupakan sebab jurutera gemar menggunakannya di kawasan yang kerap mengalami gempa bumi.

Kajian Kes: Bangunan Tinggi Menggunakan Rangka Aluminium

Bangunan 72 tingkat SkyTower di Singapura menunjukkan kemampuan struktur aluminium:

- lebih daripada 18,000 mullion aluminium suai membentuk eksoskeleton bangunan yang rintang angin

- Mengurangkan berat keseluruhan sebanyak 1,200 tan metrik berbanding alternatif keluli

- Membolehkan pemasangan 19% lebih cepat melalui pemasangan modular

Projek ini mengurangkan karbon terbenam sebanyak 34% dan mencapai pensijilan LEED Platinum, menonjolkan peranan berganda aluminium dari segi kecekapan struktur dan prestasi alam sekitar.

Reka Bentuk Mampan: Mengintegrasikan Profil Aluminium untuk Pembinaan yang Cekap Tenaga

Profil aluminium menyokong sasaran bangunan bersih-sifar melalui ciri-ciri utama:

- Kecekapan Terma : Penyekat haba poliamida dalam profil tingkap mengurangkan pemindahan haba sebanyak 60%

- Kebolehcetakan : 95% aluminium gred pembinaan dikitar semula tanpa kehilangan kualiti

- Ketahanan : Lapisan oksida semula jadi menghapuskan keperluan lapisan pelindung dalam kebanyakan persekitaran

Permukaan reflektif mereka juga meningkatkan penggunaan cahaya siang, mengurangkan keperluan pencahayaan buatan sehingga 30% dalam bangunan komersial.

Panduan Langkah demi Langkah Teknologi Pengeluaran Aluminium

Ekstrusi aluminium bermula apabila billet bulat tersebut dipanaskan pada suhu sekitar 480 hingga 500 darjah Celsius supaya menjadi cukup lembut untuk diproses. Kemudian datang proses berat di mana bahagian yang telah dilembutkan ini dipaksa melalui acuan khas menggunakan tekanan hidraulik yang boleh melebihi 15 ribu tan. Ini menghasilkan pelbagai bentuk yang tepat dari segi keratan rentas, kadangkala sepanjang 70 meter terus keluar dari mesin. Selepas ditekan, terdapat langkah penyejukan pantas yang dikenali sebagai perenyukan yang berlaku dengan cepat iaitu kira-kira 40 hingga 60 darjah per minit. Ini membantu mengekalkan sifat kekuatan logam tersebut. Apa yang berikutnya termasuklah meregangkan profil, memotongnya kepada saiz tertentu, dan pelbagai proses penuaan yang akhirnya menentukan sama ada ia memenuhi keperluan kekerasan T5 atau T6 bergantung kepada aplikasi yang akan digunakannya kelak.

Inovasi dalam Reka Bentuk Acuan dan Ketepatan untuk Profil Kompleks

Acuan keluli perkakas H13 kini menawarkan rongga ±0.05mm, membolehkan profil berongga dan berbilang rongga yang rumit. Perisian simulasi lanjutan meramal aliran logam sebelum pengeluaran, mengurangkan percubaan sebanyak 63% ( Jurnal Pembentukan Logam 2023 ). Pemanasan acuan bantuan laser mengekalkan suhu kerja optimum 500°C, mencegah kecacatan kejutan terma dalam profil gred aerospace.

Automasi dan Twin Digital dalam Kilang Ekstrusi Moden

Integrasi Industri 4.0 telah mengubah bentuk kemudahan ekstrusi dengan:

- Kawalan akuan berasaskan AI melaraskan kelajuan ram (0.1–15 mm/s) menggunakan data suhu billet masa nyata

- Twin ekstrusi maya mengesimulasikan lebih daripada 48 pemboleh ubah proses untuk mengoptimumkan hasil sebelum pengeluaran fizikal

- Sistem QC automatik menggunakan pengimbas laser 3D untuk mengesahkan dimensi pada 200 titik semakan setiap minit

Teknologi ini mengurangkan kadar sisa kepada kurang daripada 3% dan memastikan kekonsistenan 99.7% dalam pesanan berjumlah tinggi ( Rujukan Piawaian Kepakaran Aluminium 2024 ).

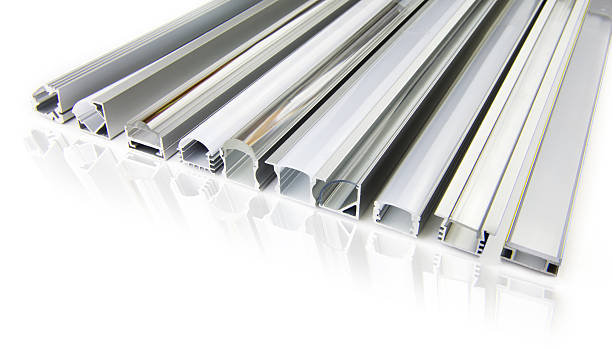

Jenis dan Pemilihan Bahan: Profil Aluminium Piawai, Suai, dan Khas

Perbandingan Aloi Aluminium Lazim: 6061 berbanding 6063 untuk Kegunaan Struktur

Antara aloi aluminium yang biasa digunakan dalam pembinaan, 6061 dan 6063 menonjol kerana sebab yang berbeza. Aloi 6061 dikenali kerana kekuatan tegangan yang mengesankan, iaitu kira-kira 240 MPa atau lebih, menjadikannya sangat sesuai untuk menyokong beban berat dalam sesuatu seperti jambatan atau mesin besar di kilang. Sebaliknya, 6063 tidak terlalu kuat tetapi memberi hasil yang cemerlang apabila permukaan licin menjadi keutamaan. Oleh itu, arkitek kerap memilih aloi ini untuk perkakas seperti tingkap dan komponen hiasan di mana rupa sama penting dengan fungsi. Apabila membina sesuatu berdekatan kawasan pantai di mana udara masin boleh merosakkan bahan, jurutera cenderung memilih 6061 kerana campuran magnesium-silikonnya yang lebih tahan terhadap karat dan haus dari masa ke masa. Gabungan kekuatan dan rintangan ini menjadikannya sangat bernilai dalam persekitaran marin.

| Harta | Aloi 6061 | Paduan 6063 |

|---|---|---|

| Kekuatan Tarik | 240–310 MPa | 150–205 MPa |

| Rintangan kakisan | Baik (anodized) | Cemerlang (oksida semula jadi) |

| Aplikasi biasa | Rangka struktur | Unsur Arkitekture |

Bilakah Perlu Memilih Profil Piawaian Berbanding Profil Reka Bentuk Khusus

Profil aluminium piawai seperti rasuk I dan alur T sangat sesuai untuk aplikasi harian seperti sistem rak atau pembinaan bingkai konveyor kerana harganya berpatutan dan mudah diperoleh. Namun, apabila keperluan menjadi lebih kompleks, profil rekabentuk khusus mula kelihatan lebih logik. Bayangkan bentuk khas yang diperlukan untuk dulang bateri kenderaan elektrik (EV) dengan saluran penyejukan terbina dalam, atau komponen ultra ringan yang diperlukan untuk aplikasi aerospace. Pengiraannya juga berbeza. Profil piawai biasanya mengurangkan masa menunggu sekitar 30% hingga 50%, tetapi apabila bekerja pada projek khusus, menggunakan profil khusus sebenarnya dapat menjimatkan kira-kira 20% bahan yang terbuang. Ini masuk akal apabila mengambil kira kedua-dua kekangan masa dan pengurusan sumber.

Aplikasi Merentasi Pembinaan, Pengangkutan, dan Infrastruktur

Profil aluminium digunakan dalam pelbagai industri:

- Pembinaan : Profil piawai membolehkan perancah yang ringan; bahagian berongga khusus menyokong dinding langsir yang cekap tenaga.

- Pengangkutan : Ekstrusi khusus mengurangkan berat kenderaan sebanyak 15–20% tanpa mengorbankan keselamatan pelanggaran.

- Infrastruktur : Profil 6061 yang tahan kakisan memanjangkan jangka hayat jambatan pejalan kaki lebih daripada 25 tahun di zon pesisir berbanding keluli.

Untuk aplikasi arkitektur seperti tingkap dan pintu, profil khas meningkatkan kecekapan terma sebanyak 30–40% melalui saluran penebat bersepadu.

Ciri-ciri Mekanikal: Nisbah Kekuatan terhadap Berat dan Prestasi Menanggung Beban

Memahami Kelebihan Nisbah Kekuatan terhadap Berat pada Profil Aluminium

Profil aluminium benar-benar menonjol apabila ia berkaitan dengan kecekapan struktur kerana kekuatannya yang mengagumkan berbanding dengan berat. Mereka mengalahkan tangan keluli dalam kategori ini, selalunya berprestasi 50 hingga 60 peratus lebih baik dalam aplikasi yang serupa. Ambil aloi 6061-T6 sebagai contoh, yang mempunyai ketumpatan sekitar 2.7 gram setiap sentimeter padu tetapi masih boleh mencapai kekuatan tegangan sehingga 300 megapascal. Ini bermakna jurutera boleh membina struktur yang lebih ringan sambil mengekalkan keupayaan membawa beban yang sama seperti bahan yang lebih berat. Kajian menunjukkan bahawa aluminium mengendalikan beban bergerak kira-kira 40 peratus paun lebih baik untuk paun daripada keluli karbon biasa. Itulah sebabnya ramai pereka lebih suka untuk bangunan yang perlu menahan gempa bumi atau mana-mana projek yang mengurangkan berat badan adalah penting.

Kajian Kes: Aluminium dalam Infrastruktur Jambatan dan Laluan Pejalan Kaki

Apabila Hamburg meningkatkan jambatan pejalan kaki Elbbrücken mereka pada tahun 2023, jurutera memilih profil aluminium 6082-T6 untuk dek. Keputusan ini mengurangkan berat sekitar 35%, namun berjaya meningkatkan kapasiti beban sehingga 5 kN per meter persegi. Rintangan bahan terhadap kakisan yang lebih baik bermaksud struktur ini dijangka tahan sekurang-kurangnya 20 tahun lebih lama daripada sebelumnya, yang sangat penting memandangkan kawasan berhampiran sungai sangat lembap. Memenuhi keperluan Eurocode 9 bukan sahaja soal memenuhi syarat; ia menunjukkan bahawa aluminium benar-benar berkesan apabila menggantikan keluli dalam projek infrastruktur penting tanpa mengorbankan keselamatan atau ketahanan.

Teknik Penguat untuk Memaksimumkan Kapasiti Struktur

Jurutera menggunakan beberapa kaedah untuk meningkatkan prestasi aluminium:

- Proses pemanasan semula (rawatan T4–T7) meningkatkan kekuatan alah sehingga 276 MPa dalam aloi 6061

- Reka bentuk profil berongga meningkatkan kekukuhan kilasan sebanyak 55% berbanding keratan padu

- Komposit hibrid menggabungkan aluminium dengan gentian karbon mencapai kekuatan mampatan melebihi 400 MPa

Disahkan melalui tolok ukur kejuruteraan ekstrusi 2024, inovasi ini membolehkan profil aluminium menyokong bangunan berbilang tingkat dan beban industri berat yang sebelum ini dikhaskan untuk keluli.

Ketahanan Terhadap Kakisan dan Ketahanan Jangka Panjang Profil Aluminium

Sains di Sebalik Lapisan Oksida Semula Jadi dalam Aluminium

Profil aluminium menentang kakisan berkat lapisan oksida pelindung yang terbentuk secara semula jadi apabila terdedah kepada oksigen. Halangan kecil ini, setebal kira-kira 2 hingga 3 nanometer, bertindak sebagai perisai terhadap kemasukan wap air dan kerosakan akibat bahan kimia. Kajian dari jurnal Corrosion Science menyokong perkara ini, menunjukkan bahawa walaupun tanpa rawatan, aloi ini mengekalkan sekitar 95 peratus daripada kekuatan asalnya selepas dibiarkan selama sepuluh tahun dalam keadaan cuaca biasa. Apa yang menjadikan aluminium begitu boleh dipercayai dari masa ke masa ialah keupayaannya untuk secara asasnya membaiki dirinya sendiri setiap kali ia tercalar atau haus, yang menerangkan mengapa jurutera meletakkan kepercayaan padanya untuk persekitaran yang mencabar di mana penyelenggaraan berkala tidak sentiasa mungkin.

Prestasi dalam Persekitaran Melampau: Zon Pesisir Pantai dan Kelembapan Tinggi

Apabila melibatkan persekitaran marin, aluminium jelas lebih unggul berbanding keluli. Sebagai contoh, aloi gred marin 5083 yang menunjukkan kadar kakisan kurang daripada 0.1 mm setahun. Kajian terkini turut meneliti bahan ini. Penyelidik bernama Diaz dan rakan-rakan pada tahun 2019 memeriksa jambatan pejalan kaki daripada aluminium yang terletak di kawasan pesisir pantai yang lembap dan mendapati sesuatu yang menarik—struktur ini masih mengekalkan sekitar 90% daripada kekuatan asalnya walaupun telah terdedah kepada air masin selama lima belas tahun. Mengapa aluminium begitu tahan? Ianya disebabkan oleh lapisan oksida pelindung yang terbentuk di permukaannya. Lapisan ini pada dasarnya menghalang ion klorida yang merosakkan daripada menembusi, iaitu faktor utama yang menyebabkan kegagalan bahan biasa dalam keadaan air laut.

Rawatan Permukaan untuk Meningkatkan Perlindungan Kakisan

Aluminium tahan lebih lama apabila dirawat dengan teknik anodisasi atau salutan serbuk. Proses anodisasi sebenarnya membina lapisan oksida semula jadi pada permukaan aluminium, kadangkala mencapai ketebalan sekitar 25 mikrometer. Salutan serbuk berfungsi secara berbeza dengan mencipta halangan pelindung yang menolak air. Peningkatan terkini dalam kaedah pengujian kakisan titisan alkali telah menunjukkan betapa berkesannya rawatan ini. Sebagai contoh, aluminium yangeanodisasi boleh menahan keadaan kabut garam selama lebih 1,500 jam, iaitu kira-kira enam kali lebih baik daripada aluminium biasa yang tidak dirawat. Ketahanan sebegini menjadikan rawatan ini penting untuk memenuhi keperluan keselamatan yang ketat dalam pelbagai bidang seperti pembinaan jambatan dan pembuatan bot, di mana bahan perlu bertahan dalam persekitaran yang keras untuk tempoh yang panjang.

Soalan Lazim

Apakah faedah menggunakan profil aluminium dalam pembinaan?

Profil aluminium menawarkan kelebihan seperti pengurangan berat, nisbah kekuatan terhadap berat yang tinggi, fleksibiliti dalam reka bentuk, rintangan terhadap kakisan, dan boleh dikitar semula, menjadikannya ideal untuk keperluan pembinaan moden.

Bagaimanakah prestasi profil aluminium di kawasan yang kerap mengalami gempa bumi?

Kelenturan semula jadi aluminium membolehkan struktur ubah bentuk secara terkawal di bawah tekanan, meningkatkan keselamatan di kawasan yang berisiko gempa bumi.

Mengapa aluminium lebih disukai berbanding keluli dalam sesetengah kes?

Aluminium lebih disukai berbanding keluli dalam situasi di mana pengurangan berat adalah penting, berkat nisbah kekuatan terhadap berat yang unggul dan rintangan terhadap kakisan.

Apakah faedah kelestarian yang ditawarkan oleh profil aluminium?

Profil aluminium menyokong kelestarian melalui ciri-ciri seperti perangkap haba yang menjimatkan tenaga, kebolehkitar semula yang tinggi, dan permukaan yang meningkatkan pencahayaan semula jadi.

Jadual Kandungan

- Peranan Profil Aluminium dalam Kejuruteraan Struktur Moden

- Panduan Langkah demi Langkah Teknologi Pengeluaran Aluminium

- Inovasi dalam Reka Bentuk Acuan dan Ketepatan untuk Profil Kompleks

- Automasi dan Twin Digital dalam Kilang Ekstrusi Moden

- Jenis dan Pemilihan Bahan: Profil Aluminium Piawai, Suai, dan Khas

- Ciri-ciri Mekanikal: Nisbah Kekuatan terhadap Berat dan Prestasi Menanggung Beban

- Ketahanan Terhadap Kakisan dan Ketahanan Jangka Panjang Profil Aluminium

- Soalan Lazim