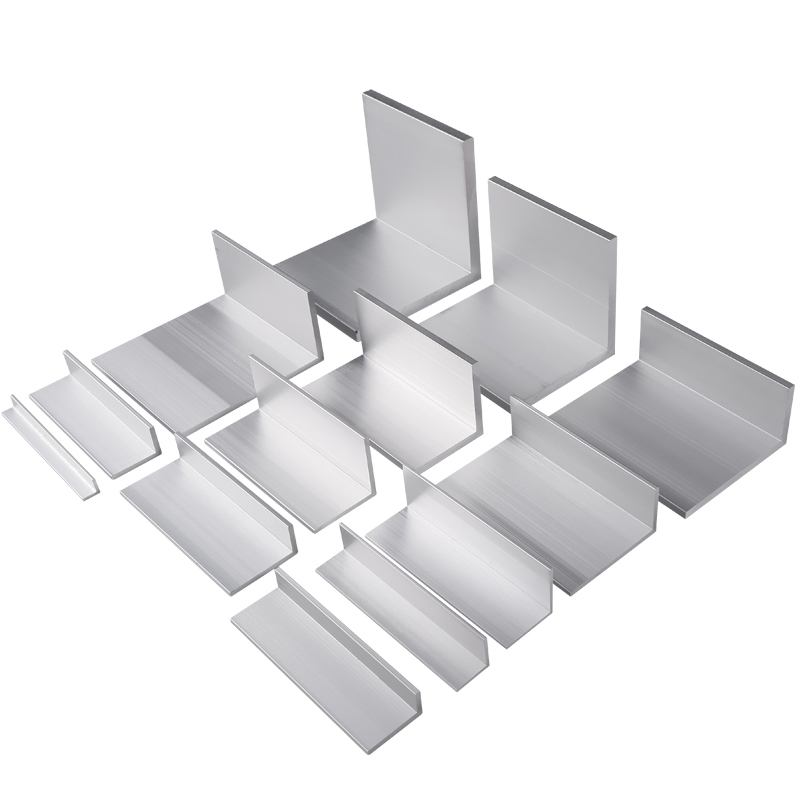

International Scope and Timely Order Accomplishment

Shandong, China serves as our headquarters while further extending our reach with branches and warehouses located in Foshan, Tianjin, South Korea, Malaysia, Vietnam, and Indonesia. With an inventory of stock upwards of 5,000 tons and over 50,000 available molds, we are able to offer expedited order delivery across our branches. Urgent orders are processed with the same efficiency. Delivery windows are set as low as 72 hours worldwide, ensuring that all customers stay on schedule regardless of their geographic location.