In recent years, with the increasing demand for aesthetically pleasing and functional materials in architectural decoration and interior design, wood grain aluminum profiles have emerged as a novel and highly sought-after material. The industry is witnessing several new trends that are driving its rapid development.

I. Rising Market Demand

Wood grain aluminum profiles are gaining popularity in both exterior and interior decoration. In the field of building facades, an increasing number of commercial buildings and residential complexes are opting for wood grain aluminum profiles over traditional materials like stone and ceramic tiles. This shift is primarily due to the profiles' ability to mimic the warm texture of wood while overcoming the drawbacks of natural wood, such as susceptibility to decay and the need for frequent maintenance. These profiles are well-suited for long-term outdoor use.

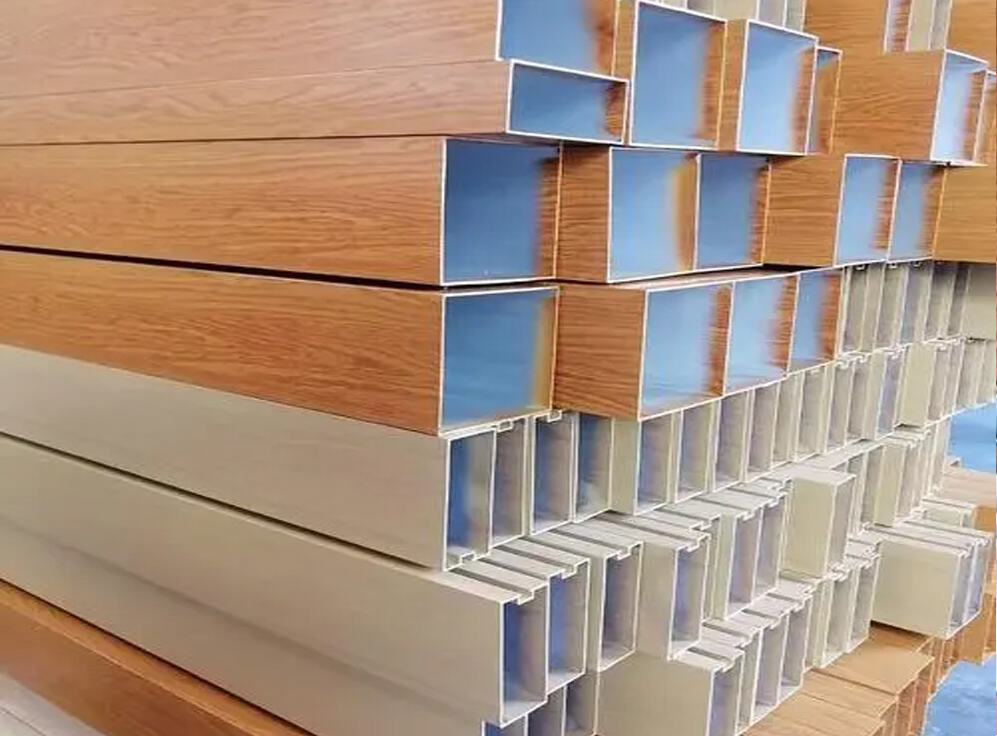

In interior decoration, wood grain aluminum profiles are widely used in various applications, including mall atrium ceilings, restaurant partitions, and balcony railings in homes. Their diverse wood grain patterns and lightweight, easy-to-install characteristics make them a favorite among designers and homeowners. This has led to a continuous increase in market demand, prompting the industry to expand its production capacity.

II. Technological Innovation

Advanced Surface Treatment: The wood grain transfer printing technology has become highly sophisticated. By using high temperature and pressure, realistic wood grain patterns are permanently printed on the surface of aluminum profiles. These patterns are not only durable and scratch-resistant but also offer superior clarity and a three-dimensional effect. Some companies have even developed special effects such as antique and scarred finishes to meet the demand for retro and personalized designs.

Structural Optimization: To enhance the strength and stability of aluminum profiles, manufacturers are innovating in the internal structure of the profiles. By using new alloy formulations to increase material toughness and incorporating honeycomb or hollow reinforcement ribs, these profiles remain lightweight while significantly improving their load-bearing capacity. This innovation has expanded their application range to include supporting structures in large-scale building facades.

III. Environmental Advantages and Policy Support

As global attention to environmental issues continues to grow, wood grain aluminum profiles offer a sustainable alternative to traditional wood products. The production process of these profiles consumes less energy and generates less pollution. Moreover, aluminum is recyclable, making it a perfect fit for the concept of sustainable development. Governments in many regions have introduced policies to promote energy-efficient buildings and green decoration, encouraging the use of environmentally friendly building materials. Wood grain aluminum profiles, with their eco-friendly characteristics, enjoy significant advantages in project bidding and government procurement, further propelling the industry towards a greener future.

Conclusion

Overall, the wood grain aluminum profile industry is accelerating its development, driven by innovation, market demand, and industry collaboration. However, it is essential to remain vigilant against external risks and seize the opportunities of the times to continue leading the trend in building decoration.