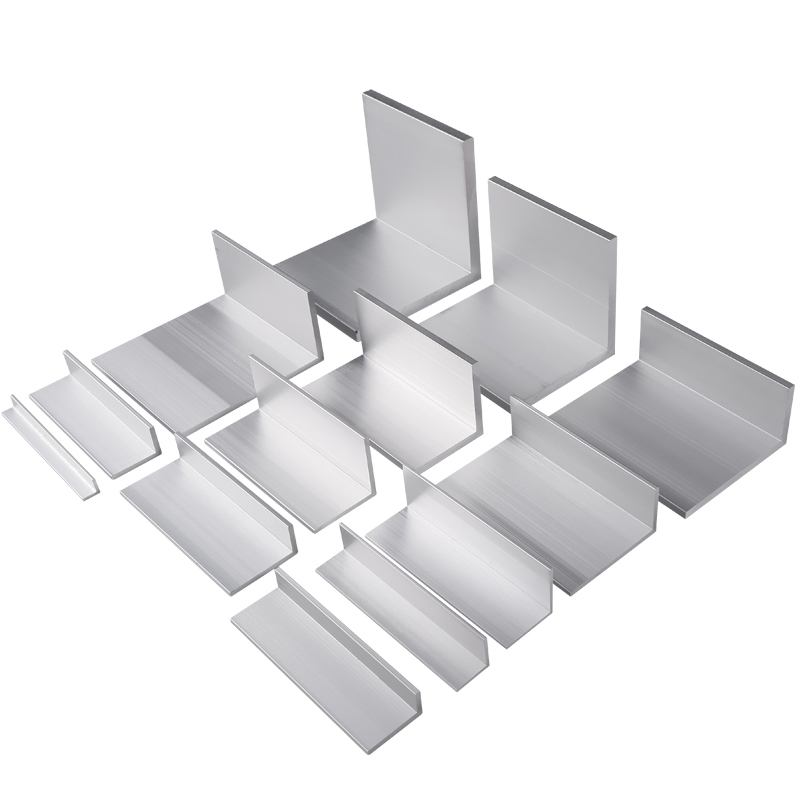

Our aluminium alloy framing systems are unique and innovative. Constructed for the commercial and structural building industry within the 1000 - 7000 series alloys, our products boast extreme strength and effortless weight which allows easy maneuverability through many building and handling restrictions. Whether you are constructing a modern exhibit publicized for commercial use, or buidling contemporary style furniture pieces, coloring polish alloys and multifunctional show pieces, these systems are modular and perfect fit for the desired effect. Extremely disassembleable and reassemlyable with no hands on effort through the right processes and techniques saves huge amounts of time. Time effective stunning pieces are unmatched by our industry competitors due to our precicisionlse machining and extruction processes. With increased adapatability and additional alapa surface treatments, our products can easily be transformed and enhanced further from their original state.