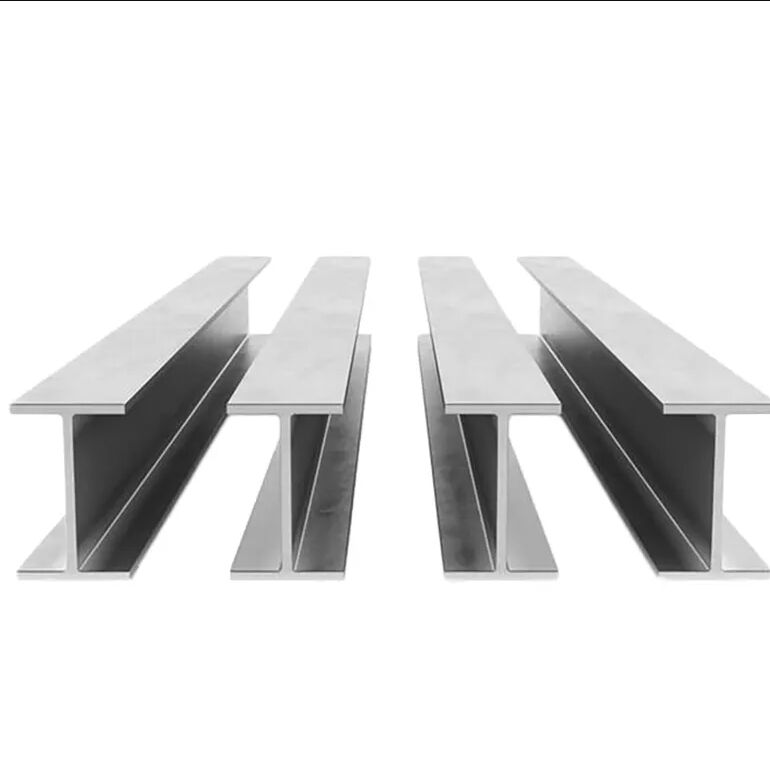

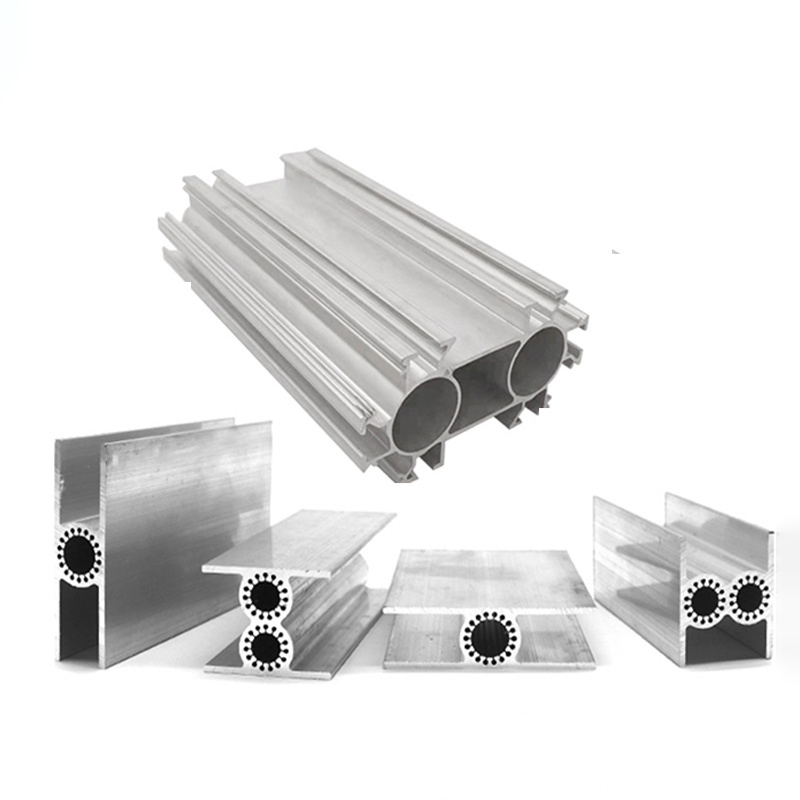

One - Stop Aluminium Profile Excellence

Worry less! We're the go - to Suppliers for everything aluminium profile related because we have been in the industry for 17 years. Your project begins with a CAD - designed 2D and 3D models of your profile which ensures that its shape and structure are precisely crafted. Our 19 extrusion machines, with a capacity range of 600 - 12,500 tons, along with 128 CNC machines, are capable of bringing the design to life. Alongside extrusion, numerous surface treatments are available, including anodizing and wood grain transfer printing. This singular service offers streamlined procurement processes with immense savings in both time and resources.