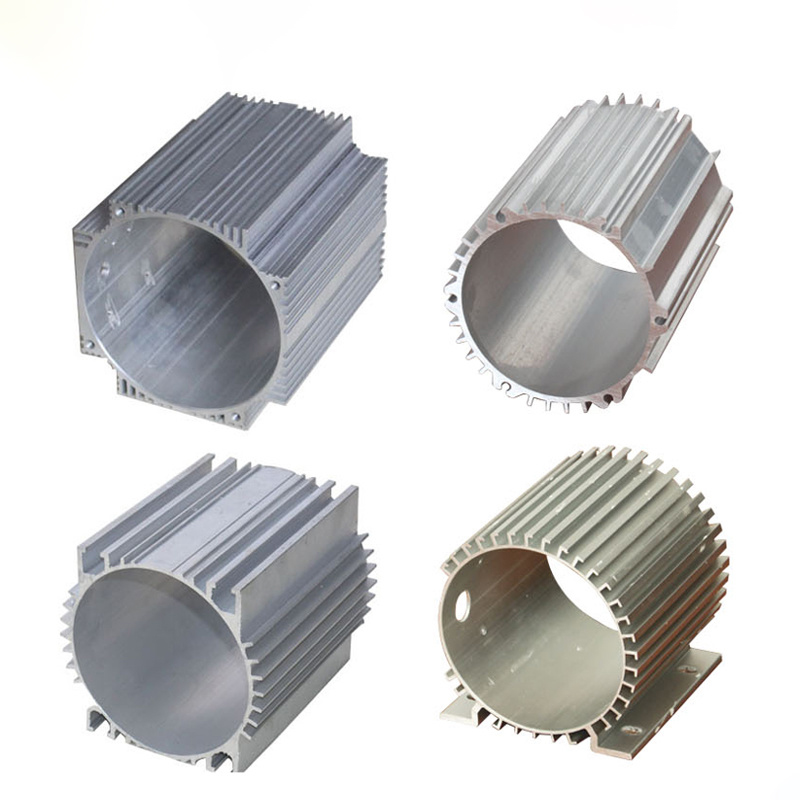

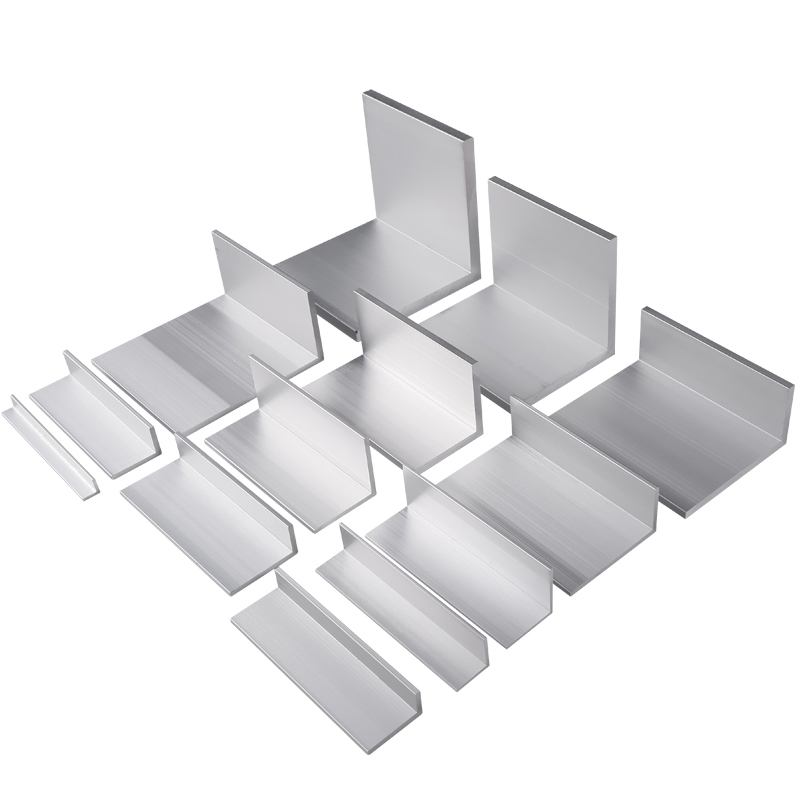

Our aluminum alloy is extremely lightweight which increases the efficacy of its use in industries like aerospace and automotive due to its high strength to weight ratio. The 1000 to 7000 series alloys are carefully engineered with consideration of fuel economy for the automotive industry, alongside the rigid weight cut restrictions for the aerospace industry. We manufacture alloys with preset qualities using 19 extrusion and 128 CNC machines. Wherever an item is designed and manufactured along with its surface treatment, extrusion, and design, processing in a singular workflow, every crafted item is guaranteed to be impeccable. Further to this, the advanced surface treatments provided to the alloys makes them not only more durable but also more beautiful. With 17 years of expertise, offering aluminum alloy products with maintained quality and ensuring on time delivery due to the global distribution network established over the years, we stand ready are these alloys are always in demand.