The Aluminium Extrusion Bottleneck: When Post-Processing Slows Production

Understanding the limitations of traditional aluminium extrusion processes

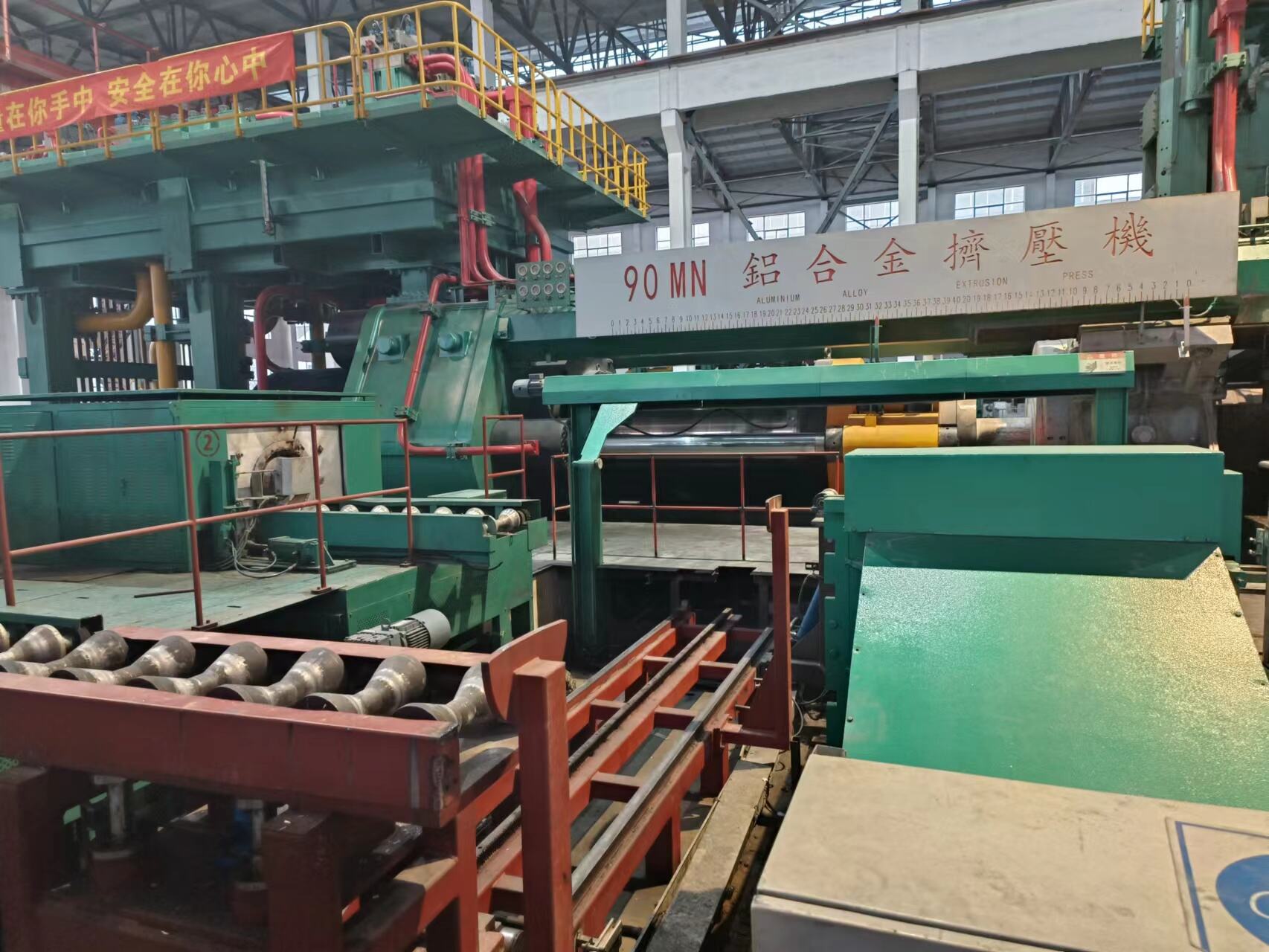

Traditional aluminium extrusion methods face inherent constraints that compound throughout production cycles. A 2023 Manufacturing Efficiency Study revealed that 15–20% of aluminium profiles require rework due to dimensional inconsistencies from die wear and thermal variance. Conventional single-axis extrusion presses struggle with:

- Profile tolerances beyond ±0.5mm without secondary machining

- Cycle times exceeding 90 seconds for complex hollow sections

- Material waste averaging 12% in trial runs (vs. 4% in optimized systems)

These inefficiencies become critical in high-volume production, where cumulative delays can erode up to 25% of potential throughput.

How slow post-processing undermines efficiency in aluminium extrusion

The primary bottleneck arises during finishing stages. Manual milling adds 3–7 days to lead times for architectural aluminium systems, while CNC machining accounts for 40% of total production time according to a 2024 industry benchmark. Key inefficiencies include:

| Factor | Traditional Process | Target Threshold |

|---|---|---|

| Surface Prep | 2–3 manual polishing stages | Automated inline finishing |

| Tolerance Adjustment | 3-axis milling requiring jig changes | 5-axis simultaneous machining |

| Quality Control | Manual inspection (5–7 mins/part) | Laser scanning (<30 seconds/part) |

Workflow fragmentation results in missed deadlines—68% of manufacturers cite post-processing delays as the leading cause.

Rising demand for faster manufacturing in high-volume aluminium production

The market is growing at around 7.2% compound annual rate until 2030 according to Grand View Research from last year, which puts manufacturers under serious strain. The automotive sector needs battery trays that meet extremely tight specifications, about plus or minus 0.2 millimeters in precision. Meanwhile, aerospace components call for complex multi-chamber profiles that must be manufactured within roughly 45 seconds per piece. Trying to handle all three key demands at once high output volumes exceeding 50 thousand linear meters each month, surfaces that need to be exceptionally smooth below 1.6 microns roughness average, and dimensional accuracy down to half a tenth of a millimeter just isn't possible using traditional manufacturing methods anymore. Companies wanting to stay competitive simply cannot afford to ignore integrated computer numerical control systems these days.

CNC Machining Integration: Accelerating Aluminium Extrusion Workflows

Reducing Cycle Times Through Seamless Integration of CNC Machining and Aluminium Extrusion

Integrating CNC machining directly into extrusion lines cuts cycle times by 40%. Synchronized workflows eliminate handling delays by enabling immediate processing of warm profiles. Facilities using integrated systems complete complex components 55% faster than those with separate departments, maintaining dimensional accuracy within ±0.05 mm.

Near-Net-Shape Extrusion: Minimizing Post-Processing with Precision-Driven Design

When advanced die designs meet 5 axis CNC machining, around 85 to 90 percent of parts actually hit their final size right after extrusion without needing much else. The near-net-shape method cuts down on scrap metal by about 22%, according to Aluminum Association data from last year, while also cutting back on those extra steps manufacturers usually have to take. Getting the tool paths just right makes all the difference too. It helps maintain consistent wall thickness throughout the part and gets those corners rounded properly. For industries like aerospace and automotive where strength matters most, these small details can mean the difference between a component that works well for years versus one that fails prematurely under stress.

Case Study: Cutting Production Time by 60% with Synchronized CNC and Extrusion Workflows

A manufacturer of heat-sink profiles reduced turnaround from 40 hours to 16 after implementing real-time data sharing between extrusion presses and CNC stations. Machine learning algorithms adjust cutting parameters based on temperature and alloy composition, sustaining ±0.1 mm tolerance across 10,000-unit batches. This integration increased annual output by 400% without expanding floor space.

Parallel Processing Power: How 128 CNC Machines Maximize Throughput in Aluminium Extrusion

Scaling Efficiency: The Impact of Multiple CNC Machines on Batch Production Timelines

Deploying 128 CNC machines in parallel reduces batch cycle times by 63% compared to single-machine setups (Manufacturing Efficiency Report 2024). Drilling, milling, and finishing occur simultaneously across identical parts, transforming linear workflows into high-throughput systems capable of scaling geometrically.

Leveraging 4-Axis and 5-Axis CNC Technology for Complex Aluminium Profiles Without Delays

Multi-axis CNC systems overcome traditional bottlenecks in fabricating intricate profiles:

- 5-axis machines complete undercuts in one setup vs. three or more on 3-axis models

- Adaptive toolpaths maintain ±0.05mm tolerances at feed rates up to 15m/min

- Automatic tool changers manage 92% of aluminum-specific tool wear scenarios

This capability enables rapid production of complex geometries without sacrificing precision or increasing changeover time.

Data Point: 128-Machine Setup Achieves 8x Throughput Versus Conventional Methods

A synchronized 128-CNC installation processes 34 tonnes of 6063 aluminum daily—equivalent to eight conventional lines—while achieving 98.6% material utilization. The configuration supports just-in-time delivery for automotive and aerospace orders exceeding 50,000 units per month.

Enabling Lights-Out Manufacturing With Advanced CNC Automation

Integrated robotics and AI-driven quality control enable continuous 24/7 operation:

- Machine vision inspects every unit in 0.8 seconds

- Predictive maintenance reduces unplanned downtime by 79%

- Energy recovery systems cut per-part power consumption by 41% versus standalone units

This automation transforms extrusion from a sequential process into a volumetric manufacturing solution.

Cost, Volume, and Production Efficiency in CNC-Enhanced Aluminium Extrusion

CNC-enhanced extrusion delivers measurable gains in cost and efficiency. A 2023 analysis of automotive component production showed a 47% reduction in per-unit finishing costs when combining extrusion with automated CNC workflows. These hybrid systems eliminate manual rework while maintaining aerospace-grade tolerances (±0.05mm).

Quantifying Time and Cost Savings in High-Volume Aluminium Part Manufacturing

Post-processing labor drops 60–80% in batches over 10,000 units. Integrated monitoring tracks key metrics:

- 12–18% material savings via near-net-shape extrusion

- 22% lower energy use per part than standalone machining

- 30% longer die life through precision alignment and reduced stress

These efficiencies scale with volume, making CNC integration particularly impactful for large runs.

Balancing Precision and Speed: Optimizing Extrusion With Efficient CNC Finishing

Modern 5-axis CNC machines achieve Ra 0.4µm surface finishes on extruded profiles without slowing production. Real-time feedback adjusts machining parameters dynamically during high-speed processing of 6000-series alloys, preventing thermal distortion and ensuring consistency.

Industry Trend: Adoption of Hybrid Production Cells Combining Extrusion and CNC

Leading manufacturers now deploy integrated extrusion-CNC cells that complete complex profiles in a single handling cycle. In a recent architectural project, this approach reduced lead times by 55% and improved first-pass yield from 84% to 98.7%, demonstrating both speed and quality advantages over decoupled processes.

Customization and Rapid Prototyping with CNC-Driven Aluminium Extrusion

Meeting Demand for Complex Designs Through CNC-Enabled Flexibility

When it comes to creating complex shapes, CNC integrated extrusion opens up possibilities that were previously only possible through casting or 3D printing methods. Manufacturers can now combine 5 axis machining with traditional extrusion processes to create profiles accurate within about 0.1 mm. These profiles include things like precisely shaped channels, smooth curved surfaces, and even built in features such as snap fit joints for assembly. According to IndustryWeek from last year, this combination approach cuts down on extra work steps by around two thirds when compared to using just dies alone. The result? More affordable production of components like heat sinks with carefully arranged fins or structural pieces that already have mounting points incorporated right into their design.

Accelerating Innovation with Rapid Prototyping in Aluminium Fabrication

CNC-driven workflows reduce prototype lead times from weeks to days by bypassing dedicated die development. Near-net-shape blanks are extruded and refined using parametric CNC programs to rapidly test variations in:

- Wall thicknesses

- Load-bearing rib configurations

- Surface finish specifications

This agility is vital in aerospace and EV battery tray development, where 78% of prototyping iterations involve adjustments under 5% (Frost & Sullivan 2024).

Modular CNC Programming for Fast Switching Between Product Variants

Advanced post-processors enable changeovers in under 30 minutes by:

| Process Step | Traditional Method | CNC-Driven Approach |

|---|---|---|

| Toolpath Generation | 4–6 hours | 15 minutes |

| Fixture Reconfiguration | Manual adjustment | Pre-mapped profiles |

| First-Article Validation | Full inspection | Laser-scan matching |

This modularity supports small batches as low as 50 units while maintaining 98.6% uptime—a decisive advantage for medical device makers needing frequent design updates.

FAQ

- What are the main bottlenecks in traditional aluminum extrusion processes? Traditional aluminum extrusion processes face bottlenecks primarily in post-processing stages like manual milling, surface preparation, tolerance adjustment, and quality control, significantly affecting production speed and efficiency.

- How does CNC machining integration improve aluminum extrusion workflows? CNC machining integration reduces cycle times by 40%, allowing for seamless and immediate processing of aluminum profiles, which cuts down on handling delays and improves precision.

- What are the benefits of near-net-shape extrusion in aluminum component manufacturing? Near-net-shape extrusion minimizes post-processing requirements, reduces scrap metal by 22%, and maintains consistent wall thickness, which is crucial for industries demanding high strength and precision.

- How does parallel processing with CNC machines impact production timelines? Using multiple CNC machines in parallel can decrease batch cycle times by 63%, streamlining production through simultaneous machining activities and greatly enhancing throughput.

- What role does automation play in modern CNC-driven aluminum extrusion? Automation, including machine vision and predictive maintenance, supports continuous 24/7 operation, reducing downtime and power consumption, ultimately transforming extrusion into a more efficient manufacturing solution.

Table of Contents

- The Aluminium Extrusion Bottleneck: When Post-Processing Slows Production

- CNC Machining Integration: Accelerating Aluminium Extrusion Workflows

- Parallel Processing Power: How 128 CNC Machines Maximize Throughput in Aluminium Extrusion

- Scaling Efficiency: The Impact of Multiple CNC Machines on Batch Production Timelines

- Leveraging 4-Axis and 5-Axis CNC Technology for Complex Aluminium Profiles Without Delays

- Data Point: 128-Machine Setup Achieves 8x Throughput Versus Conventional Methods

- Enabling Lights-Out Manufacturing With Advanced CNC Automation

- Cost, Volume, and Production Efficiency in CNC-Enhanced Aluminium Extrusion

- Customization and Rapid Prototyping with CNC-Driven Aluminium Extrusion

- Meeting Demand for Complex Designs Through CNC-Enabled Flexibility

- Accelerating Innovation with Rapid Prototyping in Aluminium Fabrication

- Modular CNC Programming for Fast Switching Between Product Variants

- FAQ