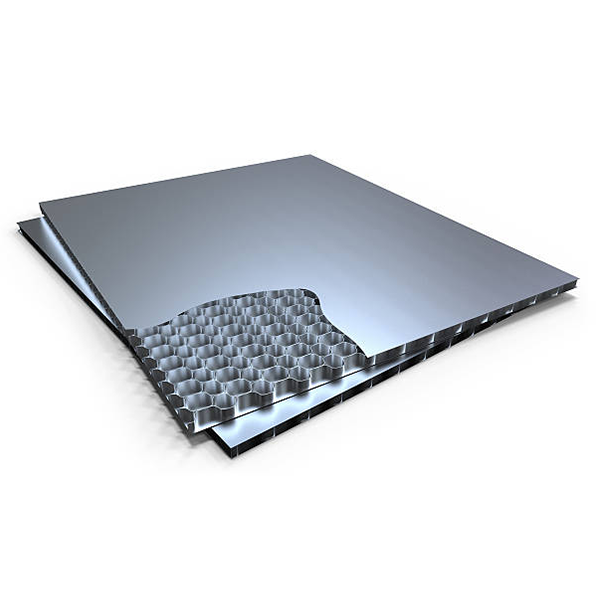

Aluminum Honeycomb Ceiling Panel

Aluminum Honeycomb Ceiling Panel is a new type of building suspended ceiling material, made by combining aluminum honeycomb core material with aluminum alloy panels.It features lightweight, high strength, fire resistance, moisture resistance, sound insulation, and thermal insulation, making it widely used in commercial buildings, public facilities, and high-end residential areas for ceiling decoration.

- Overview

- Product Specifications

- Recommended Products

Aluminum Honeycomb Ceiling Panel is a high-performance building suspended ceiling material with an aluminum honeycomb core structure that provides lightweight and high-strength characteristics.The outer layer is made of high-quality aluminum alloy panels,processed with advanced surface treatment technologies to offer a variety of color and texture options to meet different architectural styles and decoration requirements.The product has excellent fire and moisture resistance,complying with national building material standards,as well as outstanding sound and thermal insulation effects,which can effectively improve indoor acoustic environments and energy-saving performance.The installation process is simple and fast,with various installation methods available,such as keel installation and hook installation,suitable for complex spatial structures.It has good environmental performance with no harmful substance emissions,making it a green building material.The product has a long service life and low maintenance cost,providing an ideal ceiling solution for modern buildings.

Parameter

|

Parameter Name |

Parameter Value |

|

Material |

Aluminum honeycomb core + Aluminum alloy panel |

|

Size |

Customized (Common sizes: 600mm × 600mm, 1200mm × 600mm) |

|

Thickness |

3mm, 4mm, 5mm (Customizable) |

|

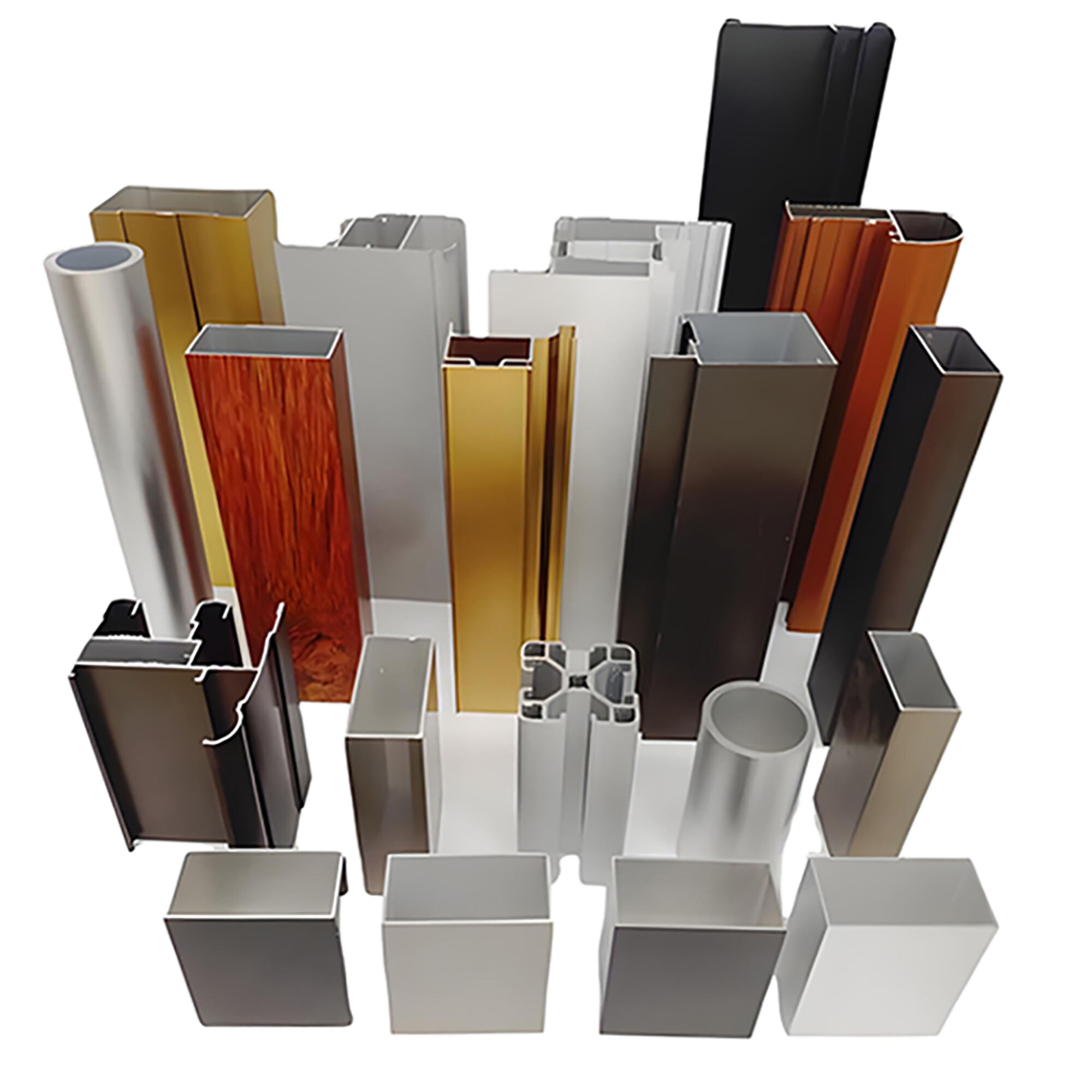

Color |

Various colors available (Matt, gloss, texture, etc.) |

|

Surface Treatment |

Fluorocarbon coating, powder coating, anodizing, etc. |

|

Fire Resistance |

Class A |

|

Moisture Resistance |

Excellent |

|

Sound Insulation |

30-40dB (Depending on thickness) |

|

Thermal Insulation |

Effective heat transfer reduction |

|

Installation Method |

Keel installation, hook installation, etc. |

|

Service Life |

Over 20 years |

|

Application Scenarios |

Commercial buildings, public facilities, high-end residences, etc. |