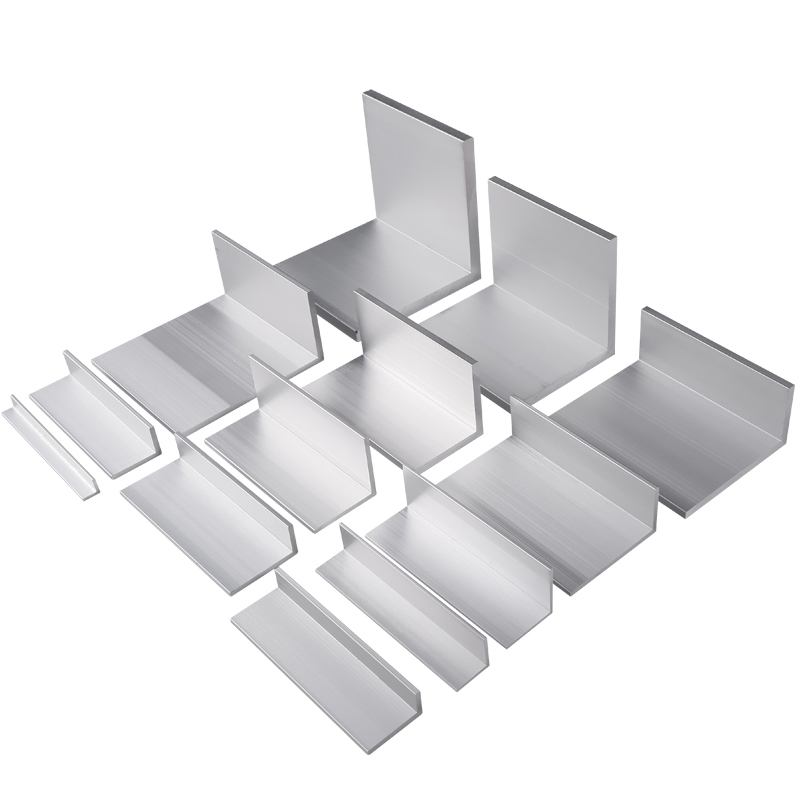

I beams I produce offer reliable architectural support as I makes use of numerous aluminum alloys and extrusion technologies. My 19 extrusion plants and 128 CNC machines coupled with the use of high grade aluminum alloys allow me to extrude I beams with precise measurements and excellent engineered properties. I beams are not only ideal for construction where structure weight reduction is needed, but also where rugged robustness of industrial machineries is required due to their remarkable strength to weight ratio. Stringent controls on material selection and final inspection processes ensures uniform quality across every batch of I beams. My global branches, coupled with the production capacity of 35 thousand tons, allows me to swiftly meet Athens' project I beam requirements.