Sustainable Design and Energy-Efficient Aluminium Profiles The Role of Eco-Friendly Materials in Modern Architecture Aluminum profiles have become really important in green building because they can be recycled over and over again. About 75 percent ...

VIEW MORE

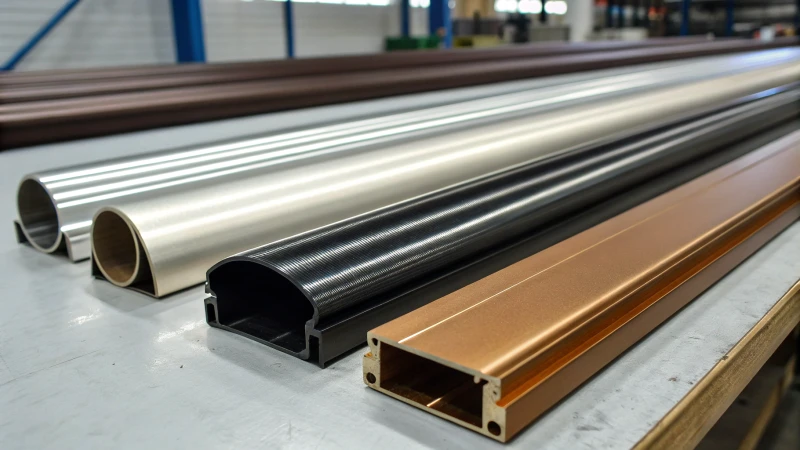

Choosing the right aluminum profile for your project is crucial for ensuring structural integrity, aesthetic appeal, and cost-effectiveness. Aluminum profiles are versatile and can be used in various applications, from construction to manufacturing ...

VIEW MORE

Anodizing is a crucial process that enhances the durability and longevity of aluminum products. This electrochemical technique not only improves the surface properties of aluminum but also provides a protective layer that significantly extends the li...

VIEW MORE

In today’s competitive market, product design is crucial for success. Custom aluminum solutions offer manufacturers a unique opportunity to enhance their product designs, providing both aesthetic appeal and functional advantages. This blog wil...

VIEW MOREAs the construction industry shifts towards more sustainable practices, aluminum profiles are emerging as a key player in this transformation. With their lightweight, durability, and recyclability, aluminum profiles offer a multitude of benefits tha...

VIEW MORE

Aluminum is widely recognized for its lightweight and corrosion-resistant properties, making it a preferred choice in various industries, from aerospace to automotive. However, to further enhance its durability and performance, innovative surface tr...

VIEW MORE

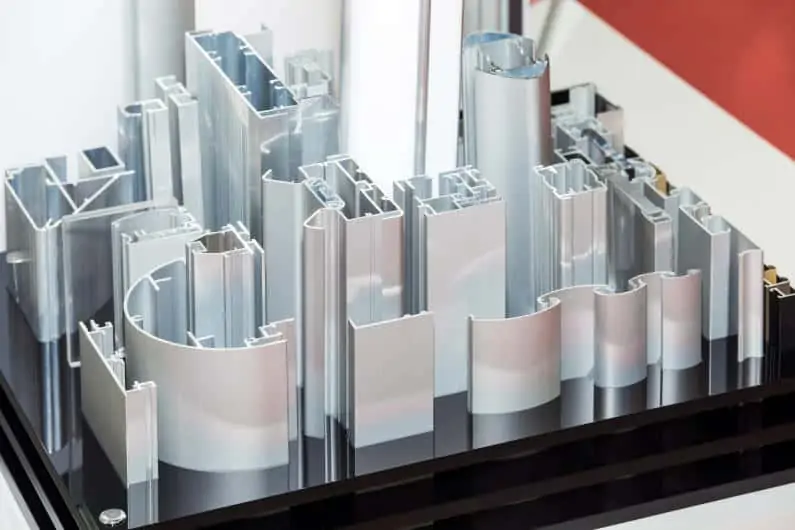

Understanding the Custom Aluminum Extrusion Process The Aluminum Extrusion Process Explained Custom aluminum extrusion works by taking solid aluminum billets and shaping them into all sorts of complicated forms using heat and pressure. First thing'...

VIEW MOREUnderstanding Custom Aluminum Fabrication The Role of Aluminum Extrusion in Design Realization Custom aluminum fabrication is possible thanks to aluminum extrusion, which allows the formation of complex shapes and sizes exactly suited to the ar...

VIEW MOREWhat is Aluminum Extrusion? Basics for Beginners Definition and Core Principles Aluminum extrusion is a key manufacturing process in which the aluminum alloy billets are forced to flow through a specifically commissioned die to produce the desi...

VIEW MOREAluminium Extrusion Profiles in Structural FrameworksHigh Strength-to-Weight Ratio AdvantagesAluminium extrusion is significantly more strong-per-mass than other material this makes it suited to structural applications. This is particularly usef...

VIEW MOREUnderstanding Aluminum Extrusion Fundamentals The Role of Aluminium Extrusion in Profile Processing Aluminum extrusion plays a key role in turning raw metal into useful shapes across many different industries. What makes this method so valuable is ...

VIEW MOREUnderstanding Aluminium Alloy Series and Classifications The 1xxx Series: Pure Aluminum and High Conductivity Aluminum alloys in the 1xxx series contain at least 99% pure aluminum, which makes them perfect for jobs needing good conductivity. That's...

VIEW MORE