Die Development: The Critical First Step in Aluminium Extrusion How Die Design Complexity Influences Aluminium Extrusion Lead Time The complexity of die design stands out as the main factor affecting how long it takes to complete an extrusion proje...

VIEW MORE

High-Precision Die Systems for Consistent Aluminium Extrusion Die geometry, H13 steel selection, and thermal management to minimize wear and distortion The shape and design of the die play a critical role in how aluminum flows during processing. By...

VIEW MORE

Optimized Die Design for Aluminium Extrusion Precision CAD/FEA-Driven Geometry Optimization to Balance Metal Flow and Meet Tolerances Getting accurate aluminium extrusions depends heavily on the shape of the dies used during production. These days,...

VIEW MORE

Lightweight Strength: Enhancing Machine Performance with Aluminium Profile Superior strength-to-weight ratio for efficient machinery design Aluminum profiles have about three times the strength to weight ratio of steel, which means engineers can bu...

VIEW MORE

Speed and Precision: How Aluminium Extrusion Delivers High-Volume Consistency Continuous Extrusion Cycles Enable Rapid Output Without Compromising Tolerance The speed of aluminium extrusion processes is pretty remarkable, thanks to continuous opera...

VIEW MORE

Understanding Key Challenges in Aluminium Extrusion Common Defects and Root Causes in Aluminium Extrusion Aluminium extrusion processes face persistent quality challenges, with surface cracks, peeling, and bubbles ranking among the most critical de...

VIEW MORE

The True Cost of Custom Aluminum Defects Common Defects in Aluminum Die Casting and Their Financial Impact Defects in custom aluminum die casting cost manufacturers an average of $74,000 annually in scrap and rework (NADCA 2022). The most costly fl...

VIEW MORE

Debunking the Myth of Limited Aluminium Profile Variety People often think there aren't many aluminum profile choices available because they only look at what's listed in those standard catalogs instead of considering what actual extrusion technolo...

VIEW MORE

Why Aluminium Profile Lead Times Delay Projects and How Stock Solves It Key Factors Causing Long Lead Times in Aluminium Profile Production Production delays for aluminium profiles come down to three big problems mostly: when things need customizin...

VIEW MORE

The Aluminium Extrusion Bottleneck: When Post-Processing Slows Production Understanding the limitations of traditional aluminium extrusion processes Traditional aluminium extrusion methods face inherent constraints that compound throughout producti...

VIEW MORE

Aluminium Profile in Modern Construction and Architecture Applications of Aluminium Profiles in Window Frames, Doors, and Curtain Walls Aluminum profiles play a big role in today's building facades because they offer good strength without being too...

VIEW MORE

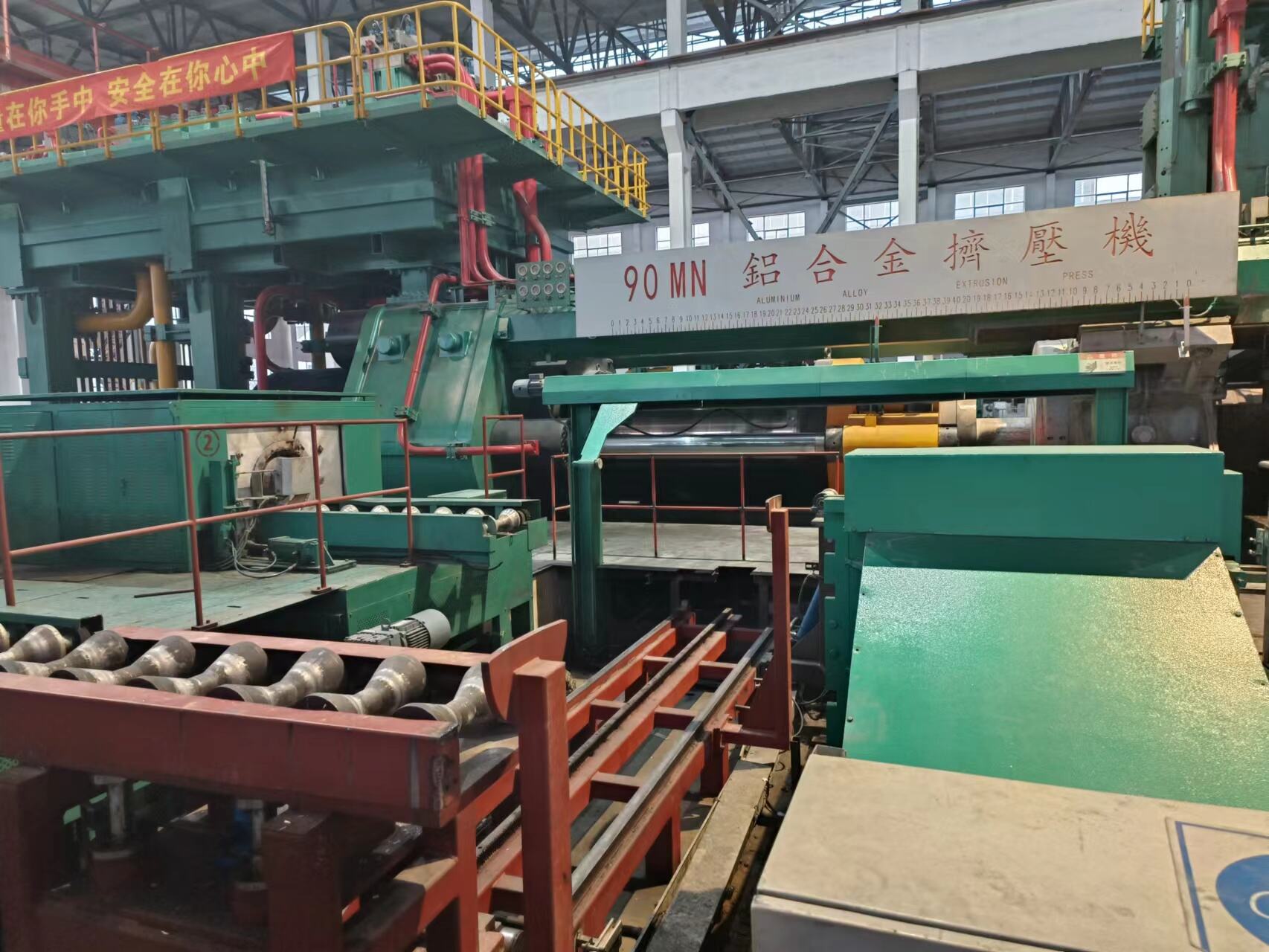

Fundamentals of the Aluminium Extrusion Process The modern aluminum extrusion process starts by heating those round billets up to around 450 to 500 degrees Celsius first. Then comes the real work pushing them through specially shaped dies at pressu...

VIEW MORE