I.Market Size and Growth Trends

In recent years,the global market for aluminum profiles has witnessed a steady growth trend.The increasing demand for lightweight and high-strength materials in various sectors such as construction,automotive,and industrial manufacturing has led to the widespread application of aluminum profiles.These materials are highly valued for their excellent properties,including light weight,corrosion resistance,and recyclability.

In the domestic market,the aluminum profile industry has also developed rapidly.China,as the world's largest producer and consumer of aluminum,has maintained the top position in global aluminum profile production for several consecutive years.The booming domestic construction industry,particularly the large-scale infrastructure construction,commercial real estate development,and the rise of residential buildings during the urbanization process,has provided a vast market space for aluminum profiles.Meanwhile,driven by the trend of automotive lightweighting,the application ratio of aluminum profiles in automotive parts manufacturing has gradually increased,further promoting the expansion of the domestic aluminum profile market.

II.Technological Innovation and Product Upgrades

A.Improvement of Production Processes

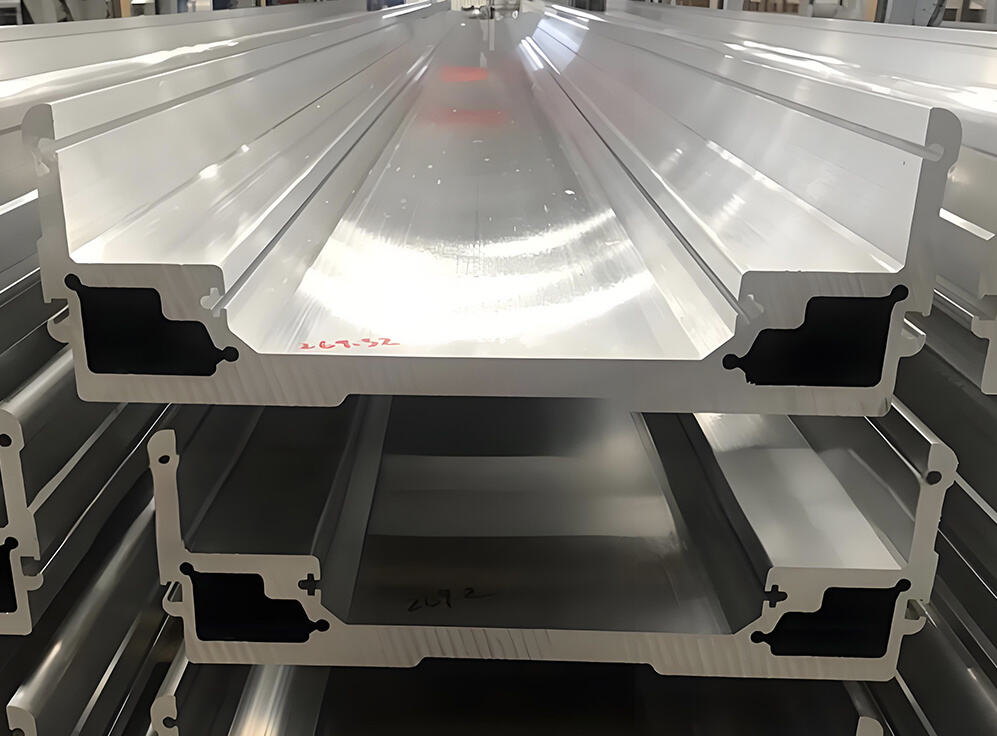

Aluminum profile manufacturers are continuously increasing their R&D investment in production processes to enhance production efficiency,reduce costs,and improve product quality.For example,new extrusion processes can achieve precise forming of aluminum profiles with more complex cross-sectional shapes,thereby increasing material utilization rates.The optimization of heat treatment processes can significantly enhance the mechanical properties of aluminum profiles,boosting their strength and hardness.In addition,surface treatment technologies have made significant progress.Innovations in processes such as anodizing,powder coating,and fluorocarbon paint spraying have not only improved the decorative and weather-resistant properties of aluminum profiles but also met personalized demands for color and gloss in various application scenarios.

B.Development of High-Performance Products

To meet the demands of high-end markets,companies are actively engaged in the research and development of high-performance aluminum profiles.The aerospace sector has extremely high requirements for the strength,low density,and high-temperature resistance of aluminum profiles,which has prompted related enterprises to develop a series of new types of aluminum alloy materials.For example,aluminum-lithium alloy profiles,which significantly reduce weight while ensuring structural strength,have provided key support for the performance improvement of aerospace vehicles.

III.Expansion of Application Fields

A.Construction Field

The application of aluminum profiles in the construction field is traditional and extensive,covering doors and windows,curtain walls,and building structural frameworks.With the popularization of green building concepts,energy-saving aluminum profiles have become a new favorite in the market.Thermal break aluminum profiles,which use thermal break technology,effectively reduce the thermal conductivity of doors and windows,enhancing the insulation and heat retention performance of buildings.They comply with national building energy-saving standards,and their market share is expanding year by year.Meanwhile,the rise of prefabricated construction has created new opportunities for aluminum profiles.As an important structural material and connecting component in prefabricated construction,the standardized and modular production of aluminum profiles is highly compatible with the construction concept of prefabricated buildings.This can significantly shorten the construction period,improve building quality,and enhance safety.

B.Automotive Field

The trend of lightweighting in the automotive industry is an important driving force for the expansion of aluminum profile applications.The use of aluminum profile components such as aluminum alloy body frames,crash beams,and car doors is gradually increasing.These components not only help reduce the weight of vehicles,lowering fuel consumption and exhaust emissions,but also improve vehicle handling and acceleration performance.In addition,the rapid development of new energy vehicles has opened up broader application space for aluminum profiles in the automotive field.Since new energy vehicles are highly concerned with range,body lightweighting is particularly important.The application of aluminum profiles in key components such as battery trays and motor housings is becoming more common.It is expected that the market demand for aluminum profiles in the automotive field will maintain high-speed growth in the coming years.

C.Industrial Field

In the field of industrial manufacturing,the application scope of aluminum profiles is also continuously expanding.They are widely used in automated production lines,mechanical equipment frames,and warehousing and logistics equipment.The ease of processing,assemblability,and good electrical conductivity of aluminum profiles enable them to meet the diverse design and manufacturing requirements of industrial equipment.For example,in automated production lines,aluminum profiles can be used as guides and supports.Their lightweight and corrosion-resistant features facilitate the installation,commissioning,and maintenance of equipment.In warehousing and logistics equipment,aluminum profile shelves have the advantages of being lightweight,high-load-bearing capacity,and easy to install,which can effectively improve the utilization rate of storage space and the efficiency of goods storage and management.

Conclusion

In summary,the aluminum profile industry is currently in a golden period of rapid development,driven by multiple factors such as market demand growth,technological innovation,and expansion of application fields.However,industry enterprises also face many challenges,such as fierce market competition and sustainable development.They need to continuously strengthen technological research and development,optimize product structures,and improve enterprise management levels to adapt to market changes and achieve long-term and stable development.